3-Piece Ball Valve

3-Piece Ball Valve

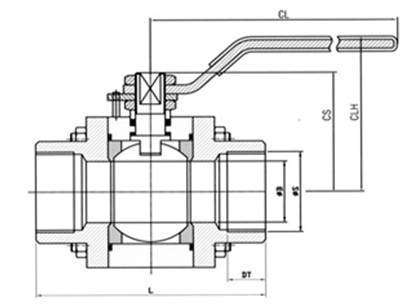

※ Size Range: 1/2″-36″

※ Class Range: 150LB-2500LB

※ Fire Safe Design

※ Anti Static

※ Anti blow-out

※ 3-Piece Ball Valve Manufacturer

Introduction

The most popular form of valve nowadays is the ball valve, which may be constructed in a range of designs to suit the needs of various sectors. For instance, a 3-Piece Ball Valve manufacturer can utilize the materials like brass, plastic, stainless steel, and other materials.

In pipelines, a ball valve is a shut-off valve that regulates the flow of fluids. A ball with an opening within a valve is rotated to control the flow of fluid. Ball valves are utilized as cut-off valves in industrial, domestic, petroleum, natural gas, and chemical storage applications.

Ball valves can be built out of a single piece, two parts, or three pieces. Although knowing the variations between one, two, and three-piece ball valves might be challenging, doing so is necessary for many procedures. Choosing the body architecture that will be most effective for your application is one of the key factors to take into account when choosing a ball valve. Compact and reasonably priced, two-piece ball valves allow for greater port sizes, while three-piece ball valves are simple to replace or repair. We hope that this post will help you better understand and select a valve by introducing the differences between a three-piece ball valve and a two-piece ball valve.

What is a 3-Piece Ball Valve?

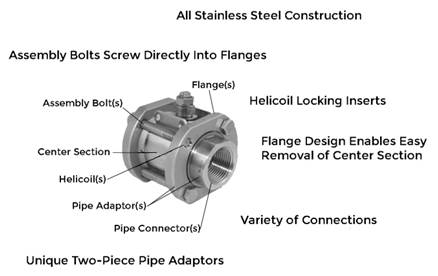

The 3-piece ball valve is made up of two connecting ends and the main body, which are joined together by these three sections. To attach to the pipeline, the end cap may be screwed, welded, flanged, or fastened. These ball valves can be constructed using carbon steel or stainless steel.

A 3-piece ball valve effectively splits the valve body from the connecting parts of the valve assembly. These would cost higher than the other two variants, although they could be useful in many applications since they allow for the removal of the valve body and trim from the pipeline system while keeping the connections in place.

The 3-piece ball valve has the benefit of being simple to disassemble. in order to maintain and clean the central body without harming the pipeline as a whole. For instance, when the valve body is clogged, all that is required to clean and maintain the ball valve is to loosen the actuator and center body bolts. After cleaning, we may use bolts to attach the center body and end cap. Because the complete valve does not need to be removed from the pipeline, our maintenance expenses are significantly decreased.

Also, the majority of three-piece ball valves have full-bore designs that enable the conveyance of additional flow.

Working: 3-Piece Ball Valve.

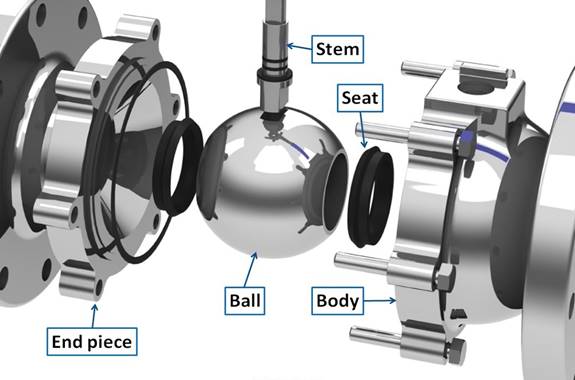

The technique by which a 3-piece ball valve operates is by spinning the valve stem to either open or close the valve. The ball valve is popular in many different industries because it is light, small in size, can be made to have a large diameter, and has numerous advantages including reliable sealing, a straightforward structure, easy maintenance, frequently closed sealing surfaces, and a spherical surface that is resistant to medium abrasiveness.

The mechanical force of the valve’s stem presses the ball toward the valve seat when the valve is in the closed state. The valve stem travels in the reverse direction as the handwheel is rotated anti-clockwise, disengaging the ball from the valve seat with its bottom angular flat. The ball starts to revolve without friction as the stem continues to raise and engages with the guide pins inside the helical grooves of the stem. The ball valve stem is raised to the limiting point and rotated to the completely open position until it approaches that point.

The ball releases the seat and starts to revolve when the handwheel is turned clockwise to shut. The stem also starts to drop. As you turn the handwheel further, the guide pin in the helical grooves on it acts on the valve stem, causing it to rotate 90 degrees together with the ball. The ball has turned 90 degrees just before shutting without coming into contact with the seat. The sphere is mechanically wedged against the bottom of the valve stem over the final few spins of the handwheel, causing it to be securely forced against the valve seat to establish a perfect seal.

Construction: 3-Piece Ball Valve.

3-piece ball valves consist of one main body structure and two pipe connections. Normally, the pipe connections are threaded or welded to the pipe. As a result, it is simple to take the main body apart for cleaning or repairs without removing the pipe connections. Options include full port and bidirectional shutdown.

Wear parts, including balls, ball seating, and the stem could be readily and separately changed after fitting a 3-piece ball valve. The valve can continue to function for the duration of its specified lifespan, providing operators with reduced long-term maintenance expenses.

Advantages & Benefits: 3-Piece Ball Valve.

- Without affecting the connections, the valve’s main body can be dismantled, preventing the service stoppage.

- Both a complete port and a bidirectional shut-off are offered by the 3-piece ball valve.

- In an extended period of time, a 3-piece ball valve saves a lot of money since it is simpler to maintain and clean.

- Simply unbolting the caps will enable you to replace the valve seals with convenience.

- Comparatively speaking, a 3-piece ball valve has a fuller connection as opposed to a one or two-piece ball valve.3-piece

- 3-piece ball valves are suitable for usage in a high-pressure vacuum.

Special Features: 3-Piece Ball Valve.

- Unlike the majority of other 3-piece valves, these valves’ end caps are secured in place by cap screws rather than by long and heavy bolts, washers, and nuts. The screws are shielded from the atmosphere outside thanks to their complete encapsulation. Even when the field is being repaired, they provide for precise alignment of the seat with the ball.

- The end cap that is welded in place and has heat-dissipating rings is another distinctive feature. Customers could install the valve in line without removing the main body thanks to these end caps, which reduces material and labor expenses.

- In contrast to one- and two-piece ball valves, 3-piece valves may be repaired without being completely removed from the line. The body comes out to allow for the removal of the seats and seals after only removing three of the four cap screws on each side.

- The special series of these valves also include an enclosed body seal and a covered seat. As a result, cold flow is prevented and long-term functionality in demanding operations is made possible. This also separates and safeguards the seats and seals from the flow stream.

Application: 3-Piece Ball Valve.

Industries that heavily rely upon or require valves should use three-piece ball valves. A three-piece valve provides versatility in terms of dismantling, servicing, and reassembly without interrupting the pipeline because these activities need frequently replacing sealants and seats.

Additionally, the ease of changing the elastomer is another benefit of valves sold by reliable three-piece valve manufacturers. This makes the valves perfect for high-cycle or demanding applications, as seen in the manufacturing industry, as they are suited for a variety of processing conditions, volumes, pressures, and even temperature levels.

The three-piece ball valve is a very recent design in the ball valve family. It offers several special benefits owing to its specialized structure, including zero friction on the switch, a seal that is unlikely to degrade, and a minimal opening and closing torque. As a result, the installed actuator is smaller. Includes a multi-turn motorized actuator that tightens the seal and changes the medium.

Differences: 3-Piece & 2-Piece Ball Valve.

- Maintenance was also considered when designing two-piece ball valves. The main distinction between the two varieties of ball valves is that the 3-piece ball valve’s body could be removed without affecting the two end caps. This is rarely possible with a two-piece ball valve, and it is actually impossible with a one-piece ball valve.

- There is a pricing difference as well. One-piece valves are often disposable, as was already said. Three-piece valves are often more expensive initially, but they can wind up being less expensive in the longer run since they are easier to maintain and can have their seats and seals changed rather than having the entire valve replaced.

Summary: 3-Piece Ball Valve.

For anywhere that requires frequent maintenance, a three-piece ball valve is suggested. The valve body is made up of three different components that are connected by bolts that are simple to remove for cleaning and maintenance. The ability to remove the central segment carrying the ball while leaving the ends of the ball valve connected to the pipe is a special benefit of the three-piece valve design. These three-piece ball valves were made with the intention of being simple to remove, clean, and reinstall. In the pharmaceutical and food/beverage sectors, three-piece stainless steel ball valves, also known as 3 SS ball valves, are frequently used for a range of hygienic purposes.

If you want to buy ball valves, you have a lot of options to choose from. Because your criteria and measurements are likely particularly precise, it is advisable to purchase from a trusted professional source even if you may locate them through traditional searches. If you have any more questions or need assistance deciding which valves would be best for your project, you may contact our valve consultants by phone or email.