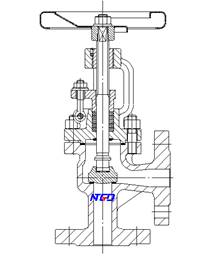

Angle Globe Valve

Angle Globe Valve

※ Size Range: 1/2〞~24〞 (DN15~DN600)

※ Class Range: CLASS 150~ CLASS 2500 (PN10~PN420)

※ Design STD.: API 600/ ASME B16.34

※ Angle Globe Valve Manufacturer

Introduction

Angle Globe Valves are basically a type of globe valves that are utilised at different angles to the pipeline. The vast majority of valves are installed perpendicular to the pipe system. The globe valves contain a valve body inside which a plug is lifted and lowered to close and open the valve. In the beginning, the Angle Globe Valve manufacturers designed the valve like a globe. Nowadays, angle globe valves come in a variety of shapes and configurations. The angle of the valve is determined by the application requirements. The angles allow users to lower the flow coefficient compared to traditional patterned valves. The Angle Globe Control Valve regulates the flow of fluid rather than entirely blocking and allowing it to flow.

Here in this informative article, we have gathered more information about angle globe valve-like their working, construction, classification, specification, and features.

What is Angle Globe Valve?

The Angle type globe valve is a design modification of a conventional globe valve with right-angle intake and exit. This valve removes the bends and has a lower pressure drop than a traditional “T” design globe valve when installed at a change in pipe direction.

The basic design construction of the stem, disc, and seal ring of an angle valve is similar to that of a conventional globe valve. The angle valve’s fluid flow makes a 90-degree turn, which is the primary distinction between the basic globe valve and the angle globe valve. These valves have less flow resistance than the globe valves with elbows that they would replace.

In addition to minimising installation time, an angle valve minimises the number of joints in a line. Because of their capacity to withstand the slugging effect of fluid flow, they are also utilised in applications with periods of pulsing flow.

Working: Angle Glove Valve

Angle Globe Valve has a working same as conventional globe valve in which handwheel or an actuator is connected with the stem of the valve, which is operated manually or remotely depending on the type of operating gear used as per requirement. A stroke in the clockwise direction starts closing the valve and in the anticlockwise direction opens the valve. Angle valves are generally assembled with a plug-type disc that seats to stop the flow and lifts to resume the flow again. The flow path in this valve offers less resistance to flow, thus, minimise the pressure drop compared to basic globe valves. These valves are also advantageous in the throttling of fluid flow.

Classification: Angle Globe Valve

Angle globe valve manufacturers can assemble the valves according to the user’s requirements and conditions that they are going to be used in. Some classifications based on various parameters are:

- Valve Disc: There are three different types of discs available, like Conventional Disc, Composition Disc & most common among all, Plug Disc.

- Stem-Disc combination: This comes in two different forms, the first is Rotating Stem with Integral and Non-Integral Disc. The second one is a non-Rotating stem with Integral and Non-Integral Disc.

- Bonnet Designs: Welded, Bolted, Flanged, & Pressure sealed bonnet, etc.

- Valve Stem Screw: Inside or Outside stem screw.

Technical Specification: Angle Globe Valve

- Size Range : ½” – 24” (DN 15 – DN 600)

- Class Standard : Class 150 – Class 2500

- Design Standard : API 600, ASME B16.34

- Temperature Range : -40 – 500°C

- End Connection : Flanged, BW, SW, Threaded

- Operation : Manual Lever / Work Gear / Pneumatic Actuator / Electrical Actuator

Feature & Benefits: Angle Globe Valve

- The angle globe valve features a simpler construction, effective sealing, great performance, and a good shape.

- Rough steel is used for the sealing surface because it is wear-resistant, corrosion-resistant, leak-proof, and has a long service life.

- The valve stem’s surface has been treated with nitride and heat tempered. It possesses great corrosion and friction resistance, as well as superior sealing and dependability.

- A major advantage of the angle globe valve is that it may be positioned at the corner of the pipe system, saving 90° elbows and making it simple to operate.

- The usage of angle-type globe valves is recommended by angle globe valve manufacturers in synthetic ammonia manufacturing plants and fertiliser factory refrigeration systems.

- Due to the high pressure required in the grinding, synthesis, and compression sections, the use of 2500LB valve design is very common in the ammonia production process. As a result, it is formed of forged steel, has high internal and exterior sealing requirements, a high fluid force on the disc, and requires the least amount of driving power while rotating. An angle globe valve can be used to meet the mentioned requirements.

Application: Angle Globe Valve

Angle globe valves are utilised in pipelines for a variety of sectors, including petroleum, mineral, pharmaceutical, fertiliser, power generation plants, recycling equipment, gas distribution, cooling and refrigeration systems, boiler steam systems, and hot oil systems. It may be used to break off or join the pipeline medium under a variety of operating situations, including nominal pressures ranging from 150 to 2500 pounds per square inch and temperatures ranging from -40 to 500 degrees Celsius.

- Angle Globe Valves are used frequently in sectors such as shipbuilding, petrochemicals, pharmaceuticals, and aircraft, among others.

- They’re utilised in cooling water systems, fuel oil systems, and other applications to regulate medium flow.

- These valves are also employed in feedwater, chemical, air, lubricant oil, and other applications where the pressure loss isn’t an issue.

- They’re best used in situations where leakage and safety are major concerns, such as high-point vents and low-point drains.

- These valves are commonly employed in control circuits to manage a broad range of flow and pressure drop due to their design.

- Its capacity to withstand a wide variety of temperatures and pressures allows it to be employed in high-pressure environments such as steam, hydraulics, and other similar applications.

Difference from Globe Valve: Angle Globe Valve

- The basic architecture of this valve is similar to that of a globe valve, but the direction of fluid flow is fundamentally different since the fluid in the angle valve turns 90 degrees.

- These valves have less flow resistance than the globe valves with elbows that they would replace.

- In addition to minimising installation time, an angle valve minimises the number of joints in a line.

- They can also be employed in applications where the pulsing flow is present because of their capacity to tolerate the slugging effect of this flow type.

- If the globe valve is positioned around a pipe bend, the angle pattern valve body offers two advantages. First, the angle pattern design has a substantially lower flow resistance than the regular pattern design. Second, the angle design reduces the number of pipe joints while also removing the requirement for a pipe elbow.

Selection Guide: Angle Globe Valve

If business owners want their valves to perform properly and last a longer life, they should select their valves properly by considering different selection points.

- As per the operating conditions of medium like Temperature, Pressure, corrosiveness, Viscosity, percentage of Suspended Solids, Toxicity, Flammability, etc.

- As per the required fluid flow characteristics like flow resistance, discharge capacity, etc.

- As per the Installation size and external size requirements like diameter, connection method, connection size with piping, weight limits, etc.

- As per the operator need like manual, or remote operation.

In addition to the above points do check for the following also.

- Look for quality-controlled direct coupled linear actuators. This ensures that the angle globe valve manufacturers were able to fulfill quality standards and objectives.

- The connected actuators should be designed in such a way that they are simple to mount. This installation should be completed without the use of any modifications, linkages, brackets, or adapters.

- The valves should be designed with water flow characteristics in mind, as well as linear flow characteristics for steam applications.

- Check the valve’s precise location to ensure that it will give the appropriate level of temperature control when in operation.

- Look for models with pressure balancing, since this will help you get a better sealing.

Top 5 Angle Glove Valve Manufacturers in the World

Company Name: Schlumberger Limited

Type of Business: Angle Globe Valve Supplier

Company’s Address: 5599 San Felipe St, Houston, TX 77056, United States

Contact Information: +971 4 274 2200

Products: Angle Globe Valve, Low Emission valve, Butterfly, Ball, Gate, Check, Plug / Diverter valves, etc.

Applications: Subsea, Drilling, Production, Gas transmission, etc.

Company Name: AVK International

Type of Business: Angle Globe Valve Manufacturer

Company’s Address: Bizonvej 1, 8464 Galten, Denmark

Contact Information: +45 87 54 21 00

Other Products: Ball, Gate, Globe, Check, Butterfly Valves, Angle Globe Valve, etc.

Applications: Fire, Wastewater, Gas, Water Distribution, etc.

Company Name: Emerson

Type of Business: Angle Globe Valve Manufacturer

Company’s Address: 8000 West Florissant Avenue, St. Louis, MO 63136, United States

Contact Information: +1 314 553 2000

Other Products: Control, Isolation, Solenoid, Relief Valves, Angle Globe Valve etc.

Applications: Nuclear Plants, Subsea, Petroleum Industry, etc.

Company Name: Bray International

Type of Business: Manufacturer

Company’s Address: 13333 Westland E Blvd # 203, Houston, TX 77041, United States

Contact Information: +1 281 894 5454

Other Products: Butterfly, Knife Gate, Control, Ball Valve, Angle Globe Valve etc.

Applications: Chemical, Food Beverages, HVAC, Marine & Shipbuilding, Mining, etc.

Company Name: Valvitalia Group

Type of Business: Manufacturer

Company’s Address: Via Tortona, 69, 27055 Rivanazzano Terme (PV), Italy

Contact Information: +39 0383 945911

Other Products: Vent Valve, Safety, PRV, Gas Blanketing, Angle Globe Valve, etc.

Applications: Subsea, FPSO, Offshore, Military, Power Plants, LNG, etc.

Summary

As discussed in the article, trunnion ball valves come under a specialized valve category with a wide range of applications, especially in industrial applications like petrochemicals. Due to its critical applications, Trunnion ball valve manufacturers focus on high safety standards, reduced operating torque, longer life span, and lower maintenance costs.

If you’re reading this post, we’d like to thank you for your time and hope you find the content informative.

Please get in touch with us for more information on trunnion ball valves and other product inquiries. You may also leave a comment and tell us what you think about our products.