API 6D Ball Valve

API 6D Ball Valve

※ Size Range: 1/2″-36″

※ Class Range: 150LB-2500LB

※ Fire Safe Design

※ Anti Static

※ Anti blow-out

※ API 6D Ball Valve Manufacturer

Introduction

The American Petroleum Institute, also known as API, is a pillar of industry-relevant, cutting-edge standards. Nearly 700 census standards have been published by the institution, which has received accreditation from the American National Standards Institute (ANSI), and which regulate several facets of the oil and gas sector, including valves.

For various valve types, API valve standards provide recommendations and suggested procedures for safety, apparatus, supervision, resources, spill prevention, and protection of the environment. These frameworks establish criteria for all producers of industrial valves and serve as a testament to good engineering practices, observance of market requirements, and the availability of premium raw materials and production techniques.

The standards for the design, manufacture, assembly, testing, and certification of ball valves and other types of valves for use in pipeline and piping installations for the petroleum and natural gas sectors are defined by the widely accepted API 6D specification. The API Monogram Program selects the best companies worldwide that have proven they can produce brand-new equipment that complies with API product criteria. Additionally necessary for API clearance is a Quality Management System that complies with API Spec Q1. Periodically, API can conduct a comprehensive audit in order to maintain the Monogram.

Pipeline Valves must adhere to API 6D specifications. The API Standard 6D is an adaption of ISO 14313, Oil and Natural Gas Industries-Pipeline Transportation Networks Valves. The ball, check, gate, and plug valves used in pipeline systems are designed, manufactured, tested, and documented in accordance with the standards laid out in this International API Standard.

API 6D ball valves are a great option for on/off operations in the power, oil & gas, and petrochemical sectors because they are built for dependability and good performance. Ball valves made to API 6D specifications are built to have a long service life and reliability.

Both API 6D trunnion mounted ball valves and floating ball valves are readily accessible. The design criteria of API 6D are met by the ball valves, which can be either full port or reduced port. A wide variety of body/bonnet materials and trims are offered for API 6D ball valves.

What is API 6D Ball Valve?

API 6D ball valves are commonly utilized for long-distance pipeline transfers. This standard specifies that in addition to switching on or off the medium, the ball valve can also perform other functions such as blowdown, clearing, overpressure relief, lubricant injecting, and on-line leak inspection. Ball valves according to API 6D have a mostly standardized architectural design. It is more important to blow down or empty out the pipeline ball valve in terms of economics and environmental preservation.

API 6D ball valves can utilize a variety of structural designs or materials to guarantee the sealing function of the valve. They could employ bodily parts with large storage capacities or increase the size of the body cavity, for instance. As a result, the seat and the ball are protected against damage caused by gravel, stones, and other foreign items remaining in the hollow for an extended period of time.

Working: API 6D Ball Valve.

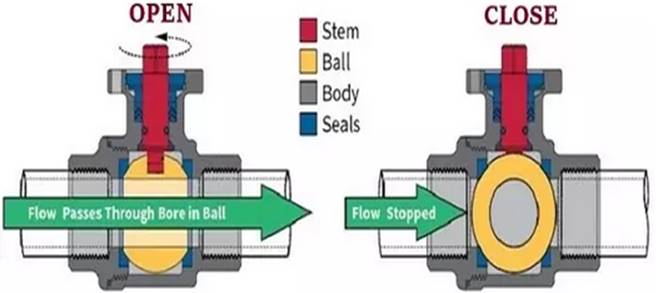

- The API 6D Ball Valve must always be in either of the two positions: fully open or fully closed. Never throttle or leave the valve in the half-open condition as this may cause damage by eroding the ball and seating surface.

- The valve gearbox or handle will display the open and closed positions of the valve. The valve can alternatively be operated by a gearbox or a motor. By turning the hand wheel counter clockwise, the valve is opened; by turning it clockwise, it is closed.

- In both the completely open and totally closed positions, the valve has position limits. It indicates that the valve is fully open or fully closed when the lever or hand wheel of the valve won’t turn any further.

- As long as the handle is parallel to the pipeline flow axis, the valve is open. On the other hand, the valve is in closed condition when the handle is perpendicular to the flow axis. A position indication will be located on the gear for gear controlled valves.

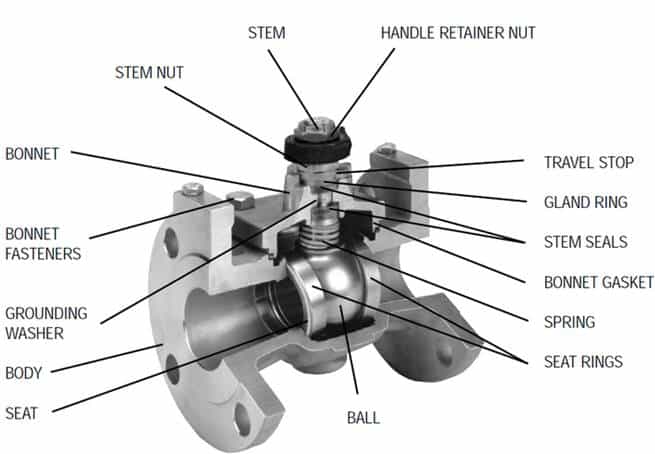

Construction: API 6D Ball Valve.

- Body: The API 6D ball valve’s valve body is the part that holds and shields the internal parts of the valve. The valve body is constructed from durable metallic alloys, including stainless steel, carbon steel, and low-temperature carbon steel.

- Handwheel: API 6D ball valve manufacturers, provide the handwheel that is used to control the fluid flow by applying torque to the handle. The actuator provides the torque required to open or close the fluid flow in automated API 6D ball valves.

- Bonnet: The upper portion of the valve body is formed by the bonnet. An API 6D ball valve’s bonnet sits atop the valve body, and the two components are joined by bolts and nuts. To safeguard the stem and packing seals, utilize the bonnet.

- Stem: The API 6D ball valve’s stem is the part that joins the ball to the actuator or handwheel. The actuator/torque handwheel is transferred to the ball through the stem, which is welded to the ball.

- Seat: The body and the ball are sealed by seats. The API 6D ball valve also uses seats to hold the ball and stop fluid leaks. The fluid that will be utilized by the valve shouldn’t corrode the material used for the seat.

- Ball: The core of the ball is hollow. In an API 6D ball valve, fluid passes through the ball’s bore. To prevent corrosion damage, the ball should be constructed from a material compatible with the fluid, much like the seats.

Technical Specification: API 6D Ball Valve.

- Design Standard : API 6D, API 608, ISO 14313, ASME B16.34, BS 5351/BS EN ISO 17292.

- Face to Face Length : API 6D, ASME B16.10

- Size Range : NPS 2” – NPS 48” (DN 50 – DN 1200)

- Pressure Range : Class 150 – Class 2500 (PN 10 – PN 420)

- Temperature Range : -254°C – 454°C (-425°F – 850°F)

- Material selection : ASTM – A216 WCB, A216WCC, A351 CF8M, A351 CNZM.

- End Connection : Ring Type (RTJ), Raised Face (RF), Special Facing (SP), Butt Weld (BW)

- Test and Inspection : API 6D, API 598

Special Features: API 6D Ball Valve.

- Double Block & Bleed: API 6D specifications are often fulfilled by trunnion-mounted ball valves. When the valve is closed, it prevents flow from both valve openings, and a bleed attachment on the body cavity allows the space between the sitting surfaces to be drained.

Online confirmation of seat sealing is made possible via an integrated Double Block & Bleed function. Even at moderate pressure differentials, spring-loaded floating seats keep contact with the ball and offer a tight shut-off. The double block and bleed process is made easier to perform by the independent closing of the upstream and downstream sides.

- Fire Safety: API 6D Ball Valves are built to be fire-safe and adhere to API 6FA, API 607, and ISO 10497 standards. Soft inserts burn during a fire, while spring assisted seats to provide metal to metal sealing.

- Body Sealing: O-rings and spiral bound gaskets work together as a double seal to provide flawless body joint sealing. The fugitive emission standards are met or achieved by API 6D Ball valves throughout a broad range of pressure and temperature operations. Both above-ground and subsurface installations are acceptable for valves.

- Blowout proof Stem: An integrated shoulder on the stem of an API 6D ball valve butts against a corresponding profile on the body to prevent blowouts. In an emergency, this capability also allows for the online changing of packing rings. Leakage to the atmosphere is prevented by a triple sealing mechanism at the stem area. It comprises of twin O-ring sealing and a graphite seal just at top of the stem assembly.

- Anti-Static: Fire risk is produced by the accumulation of static electricity brought on by friction between the ball and the soft seat material. On the stem, there is a spring-loaded plunger that ensures electrical continuity and dissipates any accumulated static charge.

- Double Piston Seat: API 6D Ball Valves are often available with Double Piston seating. In this configuration, cavity pressure controls both the upstream and downstream seats, giving the seat rings a “double piston” function that improves sealing. When dealing with the non-compressible fluids, valves with double piston seats requires an external cavity relief device.

- Double Isolation & Bleed Valve: There are two variations of DIB API 6D ball valves: DIB-1 and DIB-2. Two bi-directional seats in the DIB-1 arrangement can simultaneously seal the upstream and downstream pressures while also creating a seal between its body space and both upstream and downstream seals. The DIB-2 design has a single directional seat (SPE) on the upstream side and a single bidirectional seat (DPE) on the downstream side, allowing it to only provide the seal between the body space and the downstream seal at the same time.

Application: API 6D Ball Valve.

Around the world, API 6D ball valves are used in offshore installations, oil terminals, and processing facilities as well as cross-country pipelines. The valves have also established a reputation for themselves in operations that test the reliability and functionality of valves, such as single-buoy mooring (SBM) projects, LPG bunkers, and seawater injection pipelines. API 6D Valves provides a variety of customized solutions by relying on this well-established experience in flow control. A few such examples are:

- Cryogenic Valves: The API 6D cryogenic ball valve line is manufactured in both trunnion mounted and floating ball configurations. Pressure classes ranging from ASME 150 to 2500 and reduced bore and full bore designs are offered for the various configurations. The valve can withstand freezing temperatures as -269°C/-450°F and is designed with strict tolerances for items that will experience thermal stress and shrinkage. Additionally, given that some cryogens are combustible, the valve must be built in accordance with API 607, API 6FA, and ISO 10497 standards for fire safety.

- Corrosion resistance: Depending on the circumstances, API 6D ball valves can additionally provide a corrosion resistant coating for the valve balls and seats. Compared to solid alloys, this technique offers greater corrosion performance at a lower cost. All procedures are carried out by qualified welders in accordance with welding standards. To assure the quality of the overlay, all essential testing and checks are carried out before and after installation. These valves are provided with internal wetted components overlaid with materials like Inconel and SS316L for use in severely corrosive environments.

- Top Entry: Top Entry Ball Valves are generally welded straight to the pipeline. Even though Full Welded and Split Body Ball Valves have similar overall characteristics, the primary distinction is that the body cavity can be reached by lifting the cover without removing the valve from the line. Ball and seat rings can be taken apart and repaired, or replacement parts can be installed, with the use of some specialized maintenance tools. Since there is no need for a large area around the valve for this procedure, it can be performed with ease in a space with restricted access. Top-entry ball valves are used in essential applications where even a brief outage might result in significant expenditures. The valves are built such that they may be maintained while still in the pipeline.

Summary: API 6D Ball Valve.

Although there are other API valve specifications, API 6D is the most common. In terms of size and structural detailing, API 6D ball valve designs in this classification adhere to predetermined requirements and manufacturing guidelines. Before being approved, they undergo a thorough inspection, testing, and documentation.

Our company complies by all these rules and ensures the highest quality standards as an API 6D ball valve manufacturer. These valves are convenient for flow control in large pipelines, overpressure relief, and leak detection thanks to the API 6D ball valve design features that are advised. Each of our products meets strict media flow management requirements and has received certification as a fire safe ball valve. Despite being initially created for the petrochemical sector, their accuracy and efficiency also make them perfect for manufacturing activities with comparable requirements.

We are grateful that you are reading this and we hope the knowledge we have shared is helpful to you. Please get in touch with us if you’d like more information about our products. You can also leave a comment and share your thoughts with us.