Basket Strainer

Basket Strainer

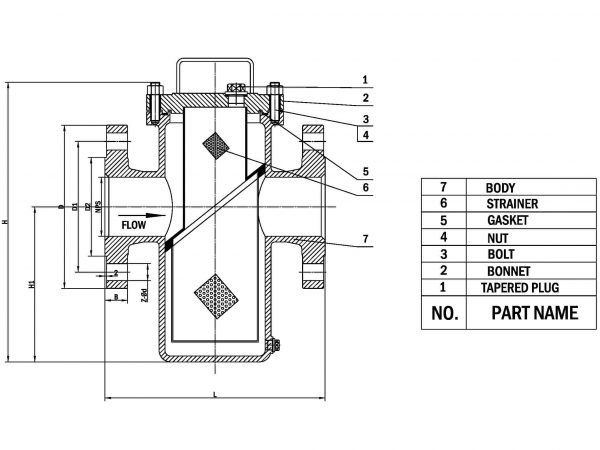

※ Basket Pattern/ Bolted Bonnet

※ Size Range: NPS 1/2 to NPS 32

※ Class Range: 150LB-2500LB

※ Design STD.: BS3532/ ASME B16.34

※ Basket Strainer Manufacturer

Introduction

Unwanted materials in a pipeline are a never-ending concern. Whether it’s seawater, fresh water, oil, paint, or a variety of food or chemical goods flowing in the system, there’s always something that might cause problems. Pumps, spray nozzles, coolers, and other similar equipment can be clogged or damaged by dirt, foreign debris, or even product clots. Because of the existence of undesired solid materials, it is sometimes required to reject a final product.

Unwanted particles are removed from the pipeline flow using basket strainers. And if we compare them to the equipment or the downtime losses, goods, or loss of production that would occur if they failed to do their function in a piping system, they are very much affordable and will be economical for the owners in a long run.

Here in this article, we will briefly learn how basket strainer manufacturers design them, how they work, their features & benefits and their applications. We will also guide you to choose the best strainer for your requirement.

What is a Basket Strainer?

Basket strainers are a type of filter that is often linked to a pump’s suction and is used to filter out particles or debris that are bigger than the mesh contained within the strainer and might otherwise harm the pump, other internal parts, or system. They are used to catch particles that are generally visible to the human eye, and the filters are utilised if the particles are smaller.

Basket strainer as defined officially by Fluid Controls Institute is “A closed vessel with cleanable

screen element designed to remove and retain foreign particles down to 0.0254 mm @ from

variable flowing fluids”

A basket strainer is also known as a pot type strainer, they are large in size than a typical Y-type strainer. The dirt holding capacity of basket strainers is greater than other types of strainers. Fluids flowing in the system fitted with the basket strainers experience a lower pressure drop as they have a large free straining area. This feature makes the basket strainers a preferred type of strainer for liquid media applications. They can also be used for the pipelines with larger diameters.

How Does a Basket Strainer work?

Working of a basket strainer is very simple. When in operation the fluid flows in through the inlet after which it enters the basket filtering element and leaves the strainer through the outlet. During this process all the solid impurities bigger than the size of mesh holes are trapped inside the basket. So, over a period of time with a continuous flow of fluid more impurities get accumulated. As a consequence of this the speed of filtration decreases over time. Also due to the continuous flow of water, sewage or any other fluid the size of the mesh holes gets narrower because of scale formation or hard deposits, which results in pressure difference of inlet and outlet.

These problems lead to frequent cleaning and maintenance of the basket strainers which results in downtime of the process. So, to overcome these problems basket strainer manufacturers developed a design with control mechanism in which a differential pressure sensor is fitted to sense the pressure difference and as this pressure difference exceeds a pre-set value it transmits an electrical signal to a controller. On receiving this signal, the controller starts the drive motor with the help of transmitting element to drive the shaft which contain a blade to scrap off all the deposits. The same controller opens the blow port which creates a low pressure area and the process of discharging the sludge begins for a short period of time until the pressure difference comes down to a minimum value and the strainer starts working normally. When the liquid enters the lower chamber of the strainer through the intake and enters the interior chamber of the strainer element through the diaphragm opening when the strainer is in operation. It’s an automatic filtration system that’s unique, effective, and simple to use. This is also called a backwash system or a backwash basket strainer.

Construction: Basket Strainer.

Basket strainers are used to safeguard machinery from getting damaged by foreign particles in the pipeline. The undesired material might be dirt or other foreign particles that find their way into the process fluid. Basket strainers are commonly used in horizontal pipelines and processes that requires high flow capacity.

The designs include a suction intake, discharge output, bolted top cover, and casing. The casing houses a filter, which is normally made of wire mesh and is used to filter particles that become caught by the mesh and sink to the bottom of the casing. Clear or solid top coverings are available. Housings may feature a drain at the bottom of the casing where sediments may sink and be discharged.

These strainers are placed upstream of equipment such as pumps, control valves, and traps to prevent corrosive or harmful debris from entering the system. To improve filtration, they can be put individually or in series. They can have a single chamber (simplex strainers) or multiple chambers (duplex strainers).

- Simplex Basket Strainer: Simplex designs are longer and broader in design, with a much bigger basket and detachable top for easy maintenance. They are designed to capture higher volumes of solids and provide smaller pressure reductions due to their increased surface area. They can only be mounted horizontally, but they are simple to examine and maintain because there is no drainage piping.

- Duplex Basket Strainer: Duplex strainers have a design that is quite similar to simplex strainers, but they include two filter baskets that may function together or independently. Because one filter may continue to work while the other is being maintained, processes can continue to run uninterrupted while being maintained.

Maintenance: Basket Strainer.

Basket strainers, unlike filters, do not need to be replaced on a regular basis as long as they are cleaned and maintained correctly. Maintaining pressure in high-flow systems is critical to a pipeline’s proper operation. Pressure gauges installed on either side of the basket strainer can detect possible obstructions in the line. The presence of pressure in the strainer indicates that it should be removed and cleaned. Failure to maintain the strainer might result in a major blockage, necessitating strainer replacement, so keep an eye on the pressure.

Regular cleanings are necessary regardless of pressure measurements to guarantee the strainer’s life. It’s vital to remember that you must depressurize the line before removing and cleaning a basket strainer, since servicing a pressurised strainer might result in personal harm or equipment damage. After removing the strainer, flush it and soak it in a cleaning solution. Scrub as needed with a brush, and don’t allow debris set on the mesh. You should have extra screens on hand to utilise during the cleaning process to avoid full system shutdowns.

Selection Guide: Basket Strainer

Each application may need the use of a particular basket strainer. Before you choose a strainer, think about the specific functions of your pipeline. The pressure and temperature specifications of your line, the kind of liquid flow (corrosive, abrasive, etc.), debris size, and cleaning and maintenance frequency are all important considerations. Consider a duplex basket strainer, which has two strainer baskets connected by diverting valves. One basket may be cleaned and maintained while the other keeps the flow going.

Summary

We are a Basket Strainer Manufacturer and tried here to explain about the Basket strainer. Please write and let us know about your views on the article.

Also, if you want to know more about Basket strainers and other industrial valves, do contact us, Thanks for your time.