Double Offset Butterfly Valve

Double Offset Butterfly Valve

※ Double Eccentric Disc

※ Size Range: NPS 2 to NPS 48

※ Class Range: PN16/25/40/150LB/300LB

※ Design STD.: API609/ MSS SP-68

※ Double Offset Butterfly Valve Manufacturer

Introduction

A double offset butterfly valve is one of the valves that can be categorized as a high-performance valve. It is also sometimes named a double eccentric butterfly valve. These valves can easily fulfill the market demand for high-performance valves that can work in extreme environments without the frequent requirement of maintenance. Double offset butterfly valve manufacturers designed these valves to provide long service life with less wear and tear of valve components.

Here in this article, we will discuss these valves in detail, their working, construction, applications, and features owing to which they have gained so much popularity.

What is Double Offset Butterfly Valve?

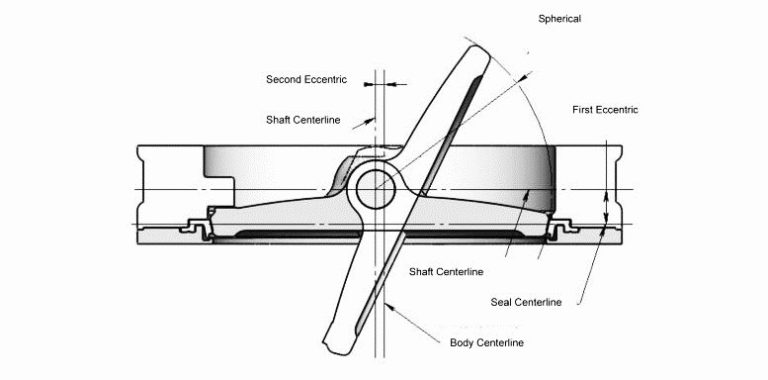

In comparison to the conventional butterfly valve, the double-offset butterfly valve features two offsets. The first offset is caused by moving the shaft slightly backward and just behind the disc rather than in the middle. Because of this first offset, the valve will have an uninterrupted 360° sealing surface on the disc.

The second offset will be the further shifting of the shaft, which is not exactly in the center of the pipe but quite to the right of it. Due to this offset design, the disc moves like a cam action and helps the disc to limit its contact with the seat. When the valve is completely open, the valve will not be in touch with the seat at all due to this offset. In this valve design contact between the seat and the disc takes place for the first 5° while opening and for the last 5° at the time of closing. The seat will encounter less friction which extends its lifespan as a result of this design which is lacking with a concentric type butterfly valve. These double-offset butterfly valves are only available in class 600 for typical usage.

When the disc starts to turn in a Double offset butterfly Valve, it moves outward from the seat rather than turning across it. The pipeline pressure in this design helps the valve disc to seal it against the valve seat. This characteristic enables double offset butterfly valves to be used in high-pressure operations like ethanol or HVAC. Its seats are typically made of PTFE or plastic; however, metal seats are available as well which also satisfy fire testing requirements such as API 607.

Construction: Double Offset Butterfly Valve

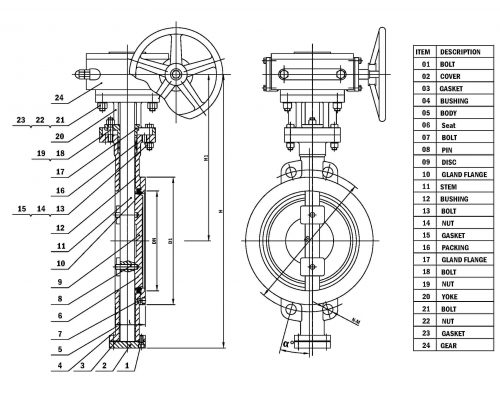

A double offset butterfly valve features a short body shape, a circular valve disc, a stem shaft, metal-to-metal or soft seating, bearings to support the shaft at the top and bottom, and a stuffing box for packing.

- Body: Customers may choose from a variety of alloys for precision cast bodies, allowing them to choose the right material for the job. The double offset butterfly valve body is cast in accordance with ASME codes. Flanged end connections, lugs construction, or wafer-style arrangements on the valve body allow it to be fitted between pipe flanges.

- Double offset butterfly valves with welding ends are typically big and facilitate the butt-welding option.

- Wafer-style butterfly valves are typically only manufactured in NPS 12 (DN 300) and smaller sizes. The size restriction is enforced mostly due to the difficulties in keeping the heavier weight valve in position between the flanges.

- The lug and flanged-end butterfly valves come in a variety of sizes and offer no complications in terms of installation between flanges, however, some issues associated with this body design are due to warped flanged surfaces and uneven bolt torquing.

- Disc: The disc is constructed with little deflection and displacement under pressure, which decreases torque and extends the life cycle of the disc. The conical edge of the disc and the offset shaft trajectory provides a “camming” action that allows the seat to be disengaged with the seat within the first few degrees of rotation. Valve discs are typically made of austenitic stainless steel, however alternative materials are available upon request. The angled sealing surface enables quick separation from the seat, reducing torque and seat wear.

- Seat: The valve seat is designed to engage between the valve body and the retainer ring, but under pressure, it can move. This eliminates the need for rubber O-ring energizers or metal backup assistance, allowing us to use solid seats that provide optimum disc edge coverage, long lifespan, and low torque. As a standard, the valve seat will be made of PTFE, RTFE, or MTFE. Seat design is freely floating and pressure aided to offer an interference and pressure-assisted seal to provide a positive seal in both directions at low and high pressures.

- Seat Retainer Plate: These precision-engineered retaining plates ensure appropriate seat stability and enable full-rated bi-directional, dead-end performance. The double offset valve seat retention ring complies with the most recent API 609 modifications, which allow spiral wound gasket sealing parts to fall beyond the bolting area.

- Bearings: For soft seated valves, stainless steel & Teflon bearing material is used, whereas, for fire safety and metal seated valves, stainless steel & graphite is used in double offset butterfly valve. Both these combinations are excellent at minimizing friction and side thrust, and they can also be used in corrosive environments.

Working: Double Offset Butterfly Valve.

The functioning of a double offset butterfly valve is nearly identical to that of a traditional butterfly valve, in which a disc with stem is connected to an actuator or lever on the valve’s exterior, and to seal the stem, a gland packing is used. When the valve is in a closed position, the disc plate is perpendicular to the fluid flow and is engaged to the valve seat. When the operator or handle turns the stem to 90 degrees, the disc travels away from the valve seat and becomes parallel with the flow. The flow can be throttled or proportionate with a partial rotation.

As a major design difference, the stem is situated behind the disc in a double offset or double eccentric butterfly valve, with an extra offset to one side. Because of the stem’s double offset design, the revolving disc only rubs on the seat for a few degrees of the initial and final movement.

Features: Double Offset Butterfly Valve.

Along with the camming action of the double offset butterfly valve it offers a power-packed performance and many features, some of those are:

- Bubble tight Sealing: Double offset Butterfly Valve ensure a bubble-tight seal for an extended period.

- Spherical Disc Design: The seat’s design and structure ensure that the seat and the disc make seamless contact. As a result, valve operation torque is minimized.

- Shaft and Disc Connection: To avoid the stem and disc engagement from loosening owing to vibration, the shaft and disc connection is provided with a pin and fastened with a nut. This also serves as additional shaft protection against blowouts.

- Shaft Protection: If the shaft to disc attachment or the shaft fails, the gland design prevents the stem from blowing out under pressure, and no piece of the shaft may be expelled from the valve.

- Reduced seat wear and extended service life with a reduced torque compared to other conventional designs.

Technical Specification: Double Offset Butterfly Valve

- Size Range : NPS 2” to NPS 72”

- Class Range : ANSI 150 to ANSI 600

- Design Standard : API 609, ANSI/ASME B16.34

- End Connection : Wafer, Lug, Double Flanged.

- Valve Body Material : Carbon Steel, Stainless Steel

- Temperature Range : -29°C to 500°C

- Seat Material : PTFE, RTFE, Inconel, 316 SS, MTFE

- Fire Standard : API 607 (fire Safe Test)

- Operation : Worm Gear, Lever, Pneumatic, Electric.

Application: Double Offset Butterfly Valve

Double offset butterfly valves with high efficiency are commonly employed in the water, chemical, and petroleum industry, but they may also be utilized in fuel management and control and a variety of other applications.

Top 5 Double Offset Butterfly Valve Manufacturers

Company Name: CMO Valves

Type of Business: Manufacturer

Company’s Address: Barrio Amategi, 142, 20400 TOLOSA, GUIPUZCOA – SPAIN

Contact Information: (+34) 943 67 33 99

Other Products: Knife Gate Valves, Slurry Valves, Check Valves, Butterfly Valves, Dampers, etc.

Applications: Water Treatment, Chemical and Petroleum Industry, Dams and Hydrological Projects, Energy Generation, Food Industry, Mining Slurry Valves, Paper Industry

Company Name: Babcock Valves

Type of Business: Manufacturer

Company’s Address: P.E. Abra Industrial, Parcela 1.5.6, 48530 Ortuella, Biscay, Spain

Contact Information: (+34) 944 536 423

Other Products: Gate, Globe, Check, Stop-check, Butterfly, Ball Valve, etc.

Applications: Power, Oil & Gas, Chemical, Petrochemical, etc.

Company Name: AVK International

Type of Business: Manufacturer

Company’s Address: Bizonvej 1, 8464 Galten, Denmark.

Contact Information: +45 87 54 21 00

Other Products: Ball, Butterfly, Control, Sluice Valves, etc.

Applications: Fire Protection, Water, Gas, Irrigation, etc.

Company Name: ACE Valve Corporation

Type of Business: Manufacturer

Company’s Address: Suite 201, 81 Dogye-Ro, Euichang-Gu, Changwon City, Kyongnam, 51162, Korea

Contact Information: Tel: (82 55) 288-1714

Other Products: Ball, Butterfly, Control, Gate, Check, Globe Valves, etc.

Applications: Oil & Gas, Fire Protection, Water, Gas, Irrigation, etc.

Company Name: Ringo Valvulas

Type of Business: Manufacturer

Company’s Address: Calle Romero, Nº6, Polígono Industrial Empresarium, 50720 Zaragoza, SPAIN

Contact Information: Tel: +34 976 45 49 40

Other Products: Ball, Butterfly, Control, Gate, Check, Globe Valves, etc.

Applications: Oil & Gas, Process Industries, Water, Gas, Irrigation, etc.

Summary

In comparison to standard butterfly valves, industrial valves have increased pressure and temperature range demands. This resulted in the development of high-performance butterfly valves capable of withstanding high pressure and high temperatures, such as a double offset butterfly valve.

We are one of the leading Double Offset Butterfly Valve manufacturers, you can contact us for more information related to this valve or any other industrial valve. Our experts will guide you to select the best valve according to your requirement from a wide range of our industrial valves.