Full Port Ball Valve

Full Port Ball Valve

※ Size Range: 2″-24″

※ Class Range: 150LB-2500LB

※ Fire Safe Design

※ Anti Static

※ Anti blow-out

※ Full Port Ball Valve Manufacturer

Introduction

The general purpose of valves is to regulate the flow of gases or liquids via a network of closed tubes or pipes. When a valve is fully open, flow through it can be somewhat unhindered. When the valve is fully closed, the flow ceases.

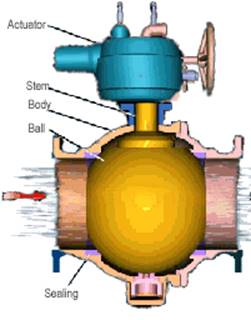

A moveable ball is housed inside the valve body of a ball valve. This spherical ball has a hole or bore running through the middle of it. When the lever of a ball valve is turned to align the ball with the pipe or tube so that it is pointed in the same direction as the pipe, the valve is opened. This permits fluids to flow through it. Additionally, the valve handle may rotate the ball to align the bore with the flow at a straight angle or 90 degrees. The ball valve is closed as a result.

Ball valves are an essential component of the process industries. The ball valve family includes a variety of styles. The full port type, standard port, v-port, and reduced port type ball valves are the four fundamental valve port designs. Full bore is a common word used in the industry meaning full port. In the valve business, the words bore and port is often used simultaneously.

The full port ball valve differs from the other ball valves in the family. This valve’s flow path takes a significantly different approach. Full port ball valve manufacturers have designed these valves in such a way that there is no resistance to flow due to the reduced cross section inside the ball. The terms full port and full bore mean the same thing and cannot be distinguished from one another. In the industrial petroleum sector, I have heard the term “full bore” used more frequently than anyplace else, but that does not mean there is a difference.

We shall now discuss what “full port” implies while discussing about the valves. A full-port valve standard means that there are no plumbing restrictions in the valve’s bore. You will not be able to notice any constraints in the pipe if a full-port ball valve is fully open in a piping design and you stare down the pipe. Only a small subset of valve types may be specified in this way, and ball valves make up the bulk of full-port valves.

What is a Full Port Ball Valve?

Full port ball valves, often known as “full bore” valves, have a unique design that permits uninterrupted flow when the valve is opened. Compared to normal valves, full port valves have bigger bodies. This enlarged body has a wider aperture and a bigger ball inside. The apertures of full port ball valves have a similar size as the nearby pipe. For instance, a 2″ full port ball valve will work with a 2″ pipeline and have an internal valve opening of 2″. Applications that demand very little to no flow pressure loss will benefit greatly from this. In the “on” or open state, a complete port valve behaves exactly as if it was not present at all. The flow is unobstructed.

There is a type of ball valve known as a “reduced port” in addition to the standard/full port valves. This implies that the aperture in the ball is less than full port valves. It is basically about one pipe size smaller. A 3/4″ reduced port valve, for example, has a 1/2″ pipe size ball opening. The velocity of increases as a result of the reduced hole.

Full bore ball valves are often more costly than reduced or regular port valves. Both or either one of them may be useful depending on the situation. But when it comes to ball valves, they all have the same function, which is to provide the system with an on/off or open/closed function.

When to employ Full Port Ball Valve?

Ball valves with full ports function similarly to those with regular ports but also have the advantage of minimizing pressure loss. This is particularly crucial to keep in mind for operations where the sustaining flow rate is essential and where the media will pass through comparatively narrow pipes with fewer changes in direction.

Full port ball valves are suggested for applications where both solids and liquids pass through the valves because they provide the minimum resistance to flow. The open construction minimizes the potential for accumulation inside and around the valve connection, which over time may impair the valve’s overall efficiency. There are a few additional aspects to consider about before picking full port ball valves.

- When pipes clog or have various issues, a pig-shaped ball or bullet with the same diameter as the pipe is used to clear the pipes. If so, the decreased bore will prevent the PIG from working since it will become trapped in it.

- One strategy is to choose reduced bore valves for services like water delivery to save money, but full-bore valves might be chosen for lines carrying process fluid.

- Often, it is based on the client’s design. For instance, a select handful of the clients with whom I have worked demanded Full throttle regardless of the service.

- Although the pressure loss in decreased bores is not significant, it must nevertheless be taken into account when choosing the right material.

Working: Full Port Ball Valve.

As was already explained, a full-bore ball valve is made out of a rotating ball with a bore equal to the pipeline for which it’s used, and thus it’s called a full port or full bore ball valve. The stem of the ball is joined to the lever through the stem. In a manually operated valve, the valve may be opened and closed by twisting the lever (it can also be done with an electric or pneumatic actuator). The hole needs to be positioned such that the fluid flow may pass through it. The ball may be spun perpendicular to the flow route to stop it.

There are two, three, or even four ports on a ball valve. A lever is used to manually open and close the majority of 2-way ball valves. The lever is parallel to the pipe when it is in the open position. The lever is perpendicular to the pipe when it is closed. Due to a fast-flowing medium and swiftly shutting the valve, manually operated ball valves are susceptible to a water hammer danger.

Ball valves can be opened and closed manually, electrically, or pneumatically. Electric motors are employed in electric ball valves to rotate the ball during valve opening and shutting. Due to its reduction gear system, there is less chance of a water hammer because the opening and closing speeds are slower.

A pneumatic actuator is used with a ball valve to spin the valve with the help of compressed air. Larger valves are frequently utilized with pneumatic actuators for improved functionality and cost efficiency.

Construction Materials & their Applications: Full Port Ball Valve.

- PVC: Polyvinyl Chloride is frequently used in the construction of valves because of its durability, flexibility, and resistance to rust. PVC full port valves often cost less and are available in a variety of shades.

- The best metallic substance that is also considered by full port ball valve manufacturers for systems that use lesser pressure is bronze, which is mixed with brass. The materials are corrosion-resistant and can last a very long period until replacements are required.

- Stainless steel is a more durable substance that has the benefits of not rusting and being able to withstand high pressures without collapsing. Full port valves manufactured out of stainless steel can withstand geothermal systems that depend on high temperatures, although they are a little bulkier and more expensive than PVC and Bronze.

- A chlorinated PVC valve is essentially the same as conventional PVC except that it can withstand greater temperatures. CPVC-made full port ball valves are suitable for use in applications that need high temperatures.

- Iron is the greatest material to use when creating ball valves that can endure high temperatures and pressures, despite the fact that it is less flexible than PVC. The only negatives of iron are its weight and susceptibility to corrosion.

Advantage: Full Port Ball Valve.

- Of all the valves available out there the biggest aperture is found in full port industrial ball valves, which makes them the best choice for working with high pressures.

- You must be particularly cautious when using the valves you decide on while working with gases and liquids.

- Their sizes make them simple to open and close.

- Due to their versatility, they can be constructed for both large- and small-scale activities. Because of this, complete port valves are most frequently found in geothermal plants.

- They may be utilized for almost anything when created with the appropriate material.

- It’s simple to do maintenance and repairs, and the system doesn’t need to be taken apart to do so.

- Full port ball valves are more efficient since they have separate, independently cleanable sections.

- Because of their superior design, they have a long lifespan and can withstand systems with high pressures and temperatures without breaking.

- This is why full port ball valves are employed by major companies all over the world.

Comparison: Full Port & Reduced/ Standard Port Ball Valve.

- Ball valves with full ports have a straight route for the passage of fluids.

- They reduce risk related to use and high-pressure drop emergencies by generating less pressure when completely open than a conventional ball valve.

- A full bore valve lowers cavitation and keeps the flow rate of different fluids constant.

- The aperture of a reduced port valve is narrower as the name suggests and more constricted than the wider one.

- The result is a stronger and more frequent pressure surge and drop.

- Since they are measured in relation to pipe diameter, hole size is objective.

- While full bore ball valves have a fluid space equal to the pipe diameter, standard ball valve apertures are narrower than the pipe diameter.

- The narrower hole structure constricts the flow, significantly raising the valve’s pressure.

Summary: Full Port Ball Valve.

A form of ball valve known as a full port ball valve has a ball opening that has the same diameter as the pipeline. For instance, if we are using a 2-inch-diameter pipe, it will be linked to a full-port ball valve that has a 2-inch-diameter ball bore. Since the flow is nearly streamlined in contrast to other valves like conventional ball valves or reduced bore ball valves, full bore ball valves assist in reducing fluid flow resistance and pressure drop. Full port ball valves function by employing a ball with a hole in the center of it. When the full port valve is open, the bore is designed to permit the flow of fluid. The ball bore of a full port ball valve is parallel to the stream when it is open. When the full port ball valve is closed, the ball bore is positioned perpendicular to the fluid flow, preventing fluid flow.

There are many different kinds of full port ball valves, including flanged full port ball valves, three-piece full port ball valves, two-piece full port ball valves, and three-way full port ball valves. Power generation, feedwater and cooling water systems, oil and gas, irrigation, and the chemical industry are just a few of the industries in that full port ball valves are employed in. Full port ball valves provide several benefits, including the ability to be maintained, cleaned, and repaired; versatility; durability; speedy operation; robust bodies; suitability for high-pressure applications; and energy efficiency.