High Performance Butterfly Valve

High Performance Butterfly Valve

※ Double Eccentric Disc

※ Size Range: NPS 2 to NPS 48

※ Class Range: PN16/25/40/150LB/300LB

※ Design STD.: API609/ MSS SP-68

※ High Performance Butterfly Valve Manufacturer

Introduction

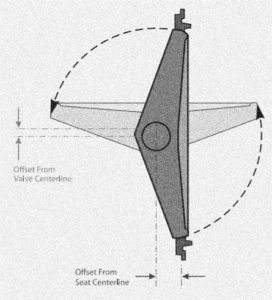

High-Performance Butterfly Valves, due to their eccentric/offset design can also term as Offset Butterfly Valves. They have a stem that does not pass through the disc’s centerline, instead, the stem is offset from it depending on the offset valve category required for the application.

For several industrial applications, like throttling control, high-performance butterfly valves are a preferred choice for business owners. When it comes to valves for demanding operations with high temperatures and pressures, it’s critical that your butterfly valve is designed to endure these pressures. In this article, we’ll talk about high-performance butterfly valves and the applications that rely on them.

What is a High-Performance Butterfly Valve?

Now, here let’s discuss what exactly distinguishes a high-performance butterfly valve from a standard butterfly valve. It is basically an eccentric disc and an offset shaft; this seems to be a small design modification but makes a lot of difference in terms of valve performance. This double offset construction gives the disc a camming movement and allows it to swing entirely away from the seat which eliminates the risk of trapping or squeezing the disc. This characteristic is not available on traditional butterfly valves. This design reduces wear areas at the top and bottom of the seat surrounding the disc, as well as the beading, pitting, and eventual ripping and leaking that follows. The disc cams firmly into the seat when closed, creating a reliable tight seal.

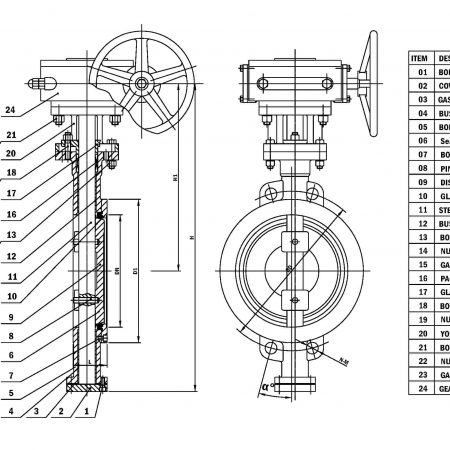

Construction: High-Performance Butterfly Valve

High-Performance Butterfly Valve manufacturers design their products in a range of body, stem, seat, disk configurations as per design standards and the requirement of the process in which they are being utilized.

- Body: These are available in a one-piece cast body design with lug, wafer, or double flanged body end connection. The one-piece body reduces the joints which reduce the leakage. These body designs also conform to fugitive emission standards.

- Seat: In HPBFV, seats are made with a unique design that incorporates a self-energizing, flexible lip seal idea that allows bi-directional sealing without the use of additional components, eliminating heat and chemical incompatibility between dissimilar materials. They come in three different seat designs:

- Spring and Pressure assisted Soft Seal.

The bi-directional bubble-tight shutdown is provided by pressure-assisted soft seats, which are available in PTFE and reinforced PTFE. Soft seat alternatives include a backup ring made of titanium or nickel-chromium alloy that uses hoop stress to generate seat memory.

- High-Temperature & Low-Temperature Metal Seal.

A metal seat made of stainless steel ensures reliable shut-off even at high-temperature operations. The metal seat can be selected with lower temperature bearings, stuffing, and coating for greater application economy. The metal seat is electroless nickel-plated and heat-treated for long-lasting performance without the use of expensive, exotic sitting materials.

- Dual Seat design.

For operations where the scaling medium can harden on the disc edge, the two-seat design is perfect. The additional metal seat protects the PTFE or RTFE seat by wiping the disc edges. High-Performance Butterfly Valve manufacturers provide a dual seat option, which combines a main PTFE soft seal with a backup stainless steel metal seat, for services that require a fire-tested valve. Even if the soft seat has been damaged by fire, this dual, bi-directional seat design guarantees good sealing.

- Stem: HPBFV features a one-piece stem shaft robust design which provides a high torsional strength to be used in high torque applications.

- Stem Retainer: A stem retainer is installed at the top of the stem to protect the stem from blowing past the compression ring if the shaft breaks within the valve.

- Disc: The disc was designed to enhance flow while minimizing resistance, resulting in a high flow coefficient (Cv).

- Disc Stop: The disc stopper is intended to keep the seat from being damaged by rotating in the wrong direction.

Features & Benefits: High-Performance Butterfly Valve

High-Performance Butterfly Valves are specifically manufactured for use in the petrochemical, oil refining, pulp and paper, sewage and wastewater, and HVAC sectors across the world. The valve was created with the concept that process industries require devices that perform well while lowering the total cost of ownership. Here, we will discuss their features and benefits.

- Offset Disk Design: The offset disc shape ensures a continuous 360-degree sealing surface. The offset disc also reduces seat-to-disc resistance, minimizing driving torque, extending cycle life, and minimizing operator size requirements. Smaller actuators cost less up front and consume less energy over time.

- One-Piece Shaft: Excellent rigidity and disc stabilization are provided by the robust one-piece stainless steel stem shaft. The one-piece shaft provides additional support, which improves alignment and ensures a tight seal.

- Disc & Shaft Pinning: Wedge-shaped tangential pins in compression load are used for providing a stronger connection between Shaft and Disc. This strong pinning guarantees that there is no wasted motion between the shaft and the disc, which is crucial for a control valve. The set screws and pins are firmly fastened, although they can be removed if repairs are required.

- Ease of Maintenance: The High-Performance valve is incredibly easy and quick to maintain. The valve can be simply dismantled if a seat, disc, or bearing needs to be changed. Internal valve components are replaceable or repairable in minutes rather than hours.

Application: High-Performance Butterfly Valve

High-performance butterfly valves are commonly employed for throttling control in systems with continuous pressure drop or sluggish process loops. They outperform typical butterfly valves for throttling applications, while also providing better efficiency and more precise flow control. Furthermore, they provide long positive bi-directional sealing in control and on-off applications.

High-performance butterfly valves in typical applications are used to regulate the flow of water, oils, air, some caustics, and other media suitable with the building materials for standard operation and when a wider temperature variety or higher pressure is necessary.

These valves also have great advantages in terms of offering dependable functioning in both regular and emergency situations. They are designed for usage in a variety of sectors, including petroleum refining and distribution processes, chemicals, maritime, and others. If the PTFE seat is damaged in a fire, the metal-seat ring of this valve design effectively prevents passage through the valve. Some special applications that they can be utilized in are vacuum shut-off, gaseous oxygen service, chlorine handling, saturated steam, high cycle operation, and also conform to NACE standards, which require sulphide stress cracking resistance.

Difference Between Conventional and High-Performance Butterfly Valve

- In the concentric butterfly valve, the shaft is engaged at the centre of the disc and located at the central axis of the pipeline while an HPBFV is offset to both disc and the pipeline axis.

- In the concentric butterfly valve, while opening and closing it, the disc and seat are always in contact or rubbing each other. But in HPBFV the contact between them reduces to minimal and while it is fully open there is no contact between them.

- Valve experience higher friction at the time of operation while in HPBFV the friction will get reduced.

- HPBFV has a greater service life as compared to concentric butterfly valves, due to which they require less maintenance.

- Concentric valve is limited to class 150 but in HPBFV class range is up to class 600 due to their seat designs.

- Concentric valves can only be employed for process on/off purpose but an HPBFV can also work as a throttling valve.

- HPBFV experience higher pressure drop as compared to concentric butterfly valves.

- Concentric valves have a lower initial cost but in a long run, the total cost of ownership of HPBFV is very less due to their features and performance.

Technical Specification: High Performance Butterfly Valve

- Size Range : NPS 2” to NPS 48”

- Class Range : ASME Class 150 to Class 2500

- Design Standard : API 609/ MSS SP-68 / ISO 5752 / BS EN 558

- End Connection : Lug, Wafer, Double Flanged

- Temperature Range : -50°C to 450°C

- Fugitive Emission : ISO 15848

- Valve Body Material : Carbon Steel / Stainless Steel (Monel)

- Stem Material : PH Stainless Steel

- Seat Material : PTFE / RPTFE / Special filled PTFE

- Seal : PTFE / RPTFE / Special filled PTFE / Graphite

- Operation : Manual Lever / Pneumatic / Electrica

Top High Performance Butterfly Valve Manufacturers

Company Name: CMO Valves

Type of Business: High Performance Butterfly Valve Manufacturer

Company’s Address: Barrio Amategi, 142, 20400 TOLOSA, GUIPUZCOA – SPAIN

Contact Information: (+34) 943 67 33 99

Other Products: Knife Gate Valves, Slurry Valves, Check Valves, Butterfly Valves, Dampers, etc.

Applications: Water Treatment, Chemical and Petroleum Industry, Dams and Hydrological Projects, Energy Generation, Food Industry, Mining Slurry Valves, Paper Industry

Company Name: Babcock Valves

Type of Business: Manufacturer

Company’s Address: P.E. Abra Industrial, Parcela 1.5.6, 48530 Ortuella, Biscay, Spain

Contact Information: (+34) 944 536 423

Other Products: Gate, Globe, Check, Stop-check, Butterfly, Ball Valve, etc.

Applications: Power, Oil & Gas, Chemical, Petrochemical, etc.

Company Name: AVK International

Type of Business: High Performance Butterfly Valve Manufacturer

Company’s Address: Bizonvej 1, 8464 Galten, Denmark.

Contact Information: +45 87 54 21 00

Other Products: Ball, Butterfly, Control, Sluice Valves, etc.

Applications: Fire Protection, Water, Gas, Irrigation, etc.

Company Name: ACE Valve Corporation

Type of Business: Manufacturer

Company’s Address: Suite 201, 81 Dogye-Ro, Euichang-Gu, Changwon City, Kyongnam, 51162, Korea

Contact Information: Tel: (82 55) 288-1714, Email: ace@acevalve.com

Other Products: Ball, Butterfly, Control, Gate, Check, Globe Valves, etc.

Applications: Oil & Gas, Fire Protection, Water, Gas, Irrigation, etc.

Company Name: DKC CO., LTD.

Type of Business: High Performance Butterfly Valve Manufacturer

Company’s Address: #34, 15Beon-Gil, Mieumsandan-1Ro, Gangseo-gu, Busan, Korea

Contact Information: Tel: +82-51-714-6030

Other Products: Triple Offset Butterfly Valves, Double Eccentric Butterfly Valves, Single Eccentric Butterfly Valves Concentric Butterfly Valves, Dual Plate Check Valves, Nozzle Check Valves, Combined Non-Return Valves, Non-Slam Non-Return Valves.

Applications: Oil & Gas, Power, Desalination, Process Industries, Water, Offshore, Shipbuilding, Irrigation, etc.

Summary

Here, in this article, we have provided detailed information about the High-performance Butterfly Valves. For more information on how to select the best valve for your need, you can contact us and our experts will guide you through our wide range of products.

Thanks for reading this article, you can write to us or give feedback in the comment box provided below.