Lubricated Plug Valve

Lubricated Plug Valve

※ Oil-Lubricated, Pressure Balance

※ Size Range: NPS 2 to NPS 32

※ Pressure Range: 150LB to 2500LB

※ Design STD.: API599/ API6D

※ Lubricated Plug Valve Manufacturer & Supplier

Introduction

Plug valves owners are primarily concerned about the problems associated with clearances and leakages. Many plug valves are made entirely of metal to give them strength in high pressure and temperature conditions. The narrow space surrounding the plug; in certain models, may enable leaking.

If the clearance gap is filled by plunging the taper plug deeper into the body, the actuation torque rises quickly, which can cause galling. So, to address this problem, plug valve manufacturers came up with an idea to fabricate the plugs with a series of grooves around the body and plug port opening, and just before the operation, these grooves are injected with a lubricant under pressure.

In this article, we will learn more about the lubricated plug valve, working & construction, types & applications

What is a Lubricated Plug Valve?

A lubricated valve, as the name suggests, uses a lubricant made mostly of basic oil and a viscosity additive that is pumped between the plug surface and the body seating at high pressure to reduce friction and seal ports. Manufacturers of plug valves typically recommend using a lubricant that is compliant with the fluid medium, and valves must be resealed after just a few cycles, if not each cycle.

By lubrication, the movement of the plug and the space between the plug and the body get sealed. Lubricant is poured into a fitting at the top of the stem, which flows down the passage, through the plug top to the grooves on the plug, and down to a well that is below the plug. This pressurised lubricant passage is fitted with a check valve to keep the lubricant under pressure & to prevent backflow when more pressure is exerted at the time of operation.

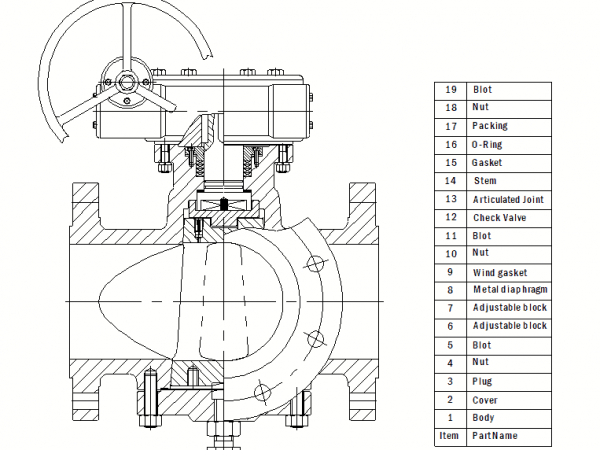

Construction: Lubricated Plug Valve.

Lubricated Plug valves consist of all the parts that are present in a conventional plug valve.

- Body: The body is cast in place and carefully machined for optimal flow. The plug, which serves as a sealing part, is housed in the body. The body must contain provisions for connecting to the pipeline, fluid holding strength requirements, plug seating region, lubrication mechanism, and stem seal.

- Plug: For leak resistance, the plug is carefully machined with a grinding finish to be matched with the body seat. Grooves are included to aid in lubricant and sealant. According to the need, several flow passages can be made available.

- Cover: The cover is attached to the bottom of the body by studs and nuts. This cover is made to withstand a lot of pressure while still complementing the body’s surface.

- Stem: The stem has a burnished surface for lower torque and adequate strength for smooth plug movement.

- Gear Box: For smooth functioning, a quarter-turn gearbox of robust design is used. Wrench, Gear, and other operators are available.

- Injector: Injectors are placed on the body to infuse lubricant into the body and to seal the stem in the event of an emergency.

- Lubricant: The lubricant works as a structural component of the valve, as it offers a flexible and renewable seat. To achieve a seal, this removes the need for force fits and metal-to-metal distortable-seat connections. To avoid the damaging effect of the line fluid and to produce an impermeable seal around each body port, even under pressure, the lubricant must display adequate elasticity as well as protection against the solvents and chemicals. The lubrication coating also prevents corrosion on the metal surfaces between the plug and the body. The lubricant seal created by the lubricant flowing through a series of lubrication grooves that round each port helps to keep the necessary layer on the metal closure surfaces.

Types: Lubricated Plug Valve

Due to taper locking, all valves are safeguarded against the potential of seizure. Taper locking is induced by a force imbalance exerted on the plug as a result of line pressure entering the bottom portion of the plug chamber. The resultant force tends to drive the plug higher, locking it in its tapered bore. The plug continues to remain in a locked position even when line pressure is lowered later on.

Traditional valves use the pressure of the plug sealant operating on the upper face of the plug to respond against the upwards force in an attempt to prevent taper locking. This lessens, but does not eliminate, the risk of taper locking, and therefore needs regular sealant injection to keep the valves free.

These valves can be divided into two different types based on plug balancing.

- Conventional Oil Lubricated Plug Valve: The plug cone is installed in a positive position for a traditional metal seat lubricated plug valve. The valve employs the sealing design of the sealing grease lubrication seat to decrease stress between the valve body and the sealing surface of the plug. The pressurised sealing oil is injected from the high-pressure oil injector which produces a seal ring surrounding the plug, layer of oil film is formed between the valve body and the sealing surface of the plug cone that may be sealed and lubricated while being easy to open and shut.

- Pressure Balanced Lubricated Plug Valves: The inverted plug design, together with the dynamic and pressure balanced construction, ensures that no locking occurs, which has been an issue with traditional designs at higher pressures.

The advantage of a dynamic pressure balancing plug valve is that it guarantees that the pressure between the plug and the upper and lower body chambers is balanced. The two holes in the plug that link the plug ports to the upper and lower chambers balance the pressure. A check valve is installed in the top end hole to ensure that the pressure in the smaller chamber is always equal to or higher than the line pressure in the bigger chamber.

Technical Specification: Lubricated Plug Valve

- Size Range : NPS 1/2 to NPS 56

- Class Range : 150LB to 2500LB

- Design Standard : API6D / API599

- Fire Standard : API 6FA

- End Connection : RF / Threaded / BW

- Operation : Manual Lever / Pneumatic / Electrical

- Pressure Rating : ANSI Class 150 to Class 2500

- Temperature Range : -29°C to +180°C

- Pressure Testing : API 598 / API 6D / EN 12266-1/ISO 5208

Application: Lubricated Plug Valve

Lubricated Plug valves have a strong structure and are easy for in-line maintenance. These valves are employed in situations where there are pulsing or static high pressures. They can withstand pressures of over 2500 pounds per square inch. These valves are ideal for media utilised in a variety of sectors, including petroleum, chemical, pharmaceutical, chemical fertiliser, and electric power. Lubricated plug valves are less prone to seizing or wear, and in some operating situations, they may have a slight increase in corrosion resistance

Top 5 Lubricated Plug Valve Manufacturers

Company Name: Eriks VE

Type of Business: Manufacturer

Company’s Address: Polígono El Abra Industrial, Parcela 1.5.5, 48530, Biscay, Spain

Contact Information: Phone: +34 946 48 01 70

Other Products: High-intensity double block & bleed Dual expanding Plug valve.

Applications: Tank storage, refinery, bulk loading, naval and aviation, refueling- and metering systems.

Company Name: Omni Valve

Type of Business: Manufacturer

Company’s Address: 4520 Chandler Rd, Muskogee, OK 74403, United States

Contact Information: Phone: +1 918-687-6100,

Other Products: Hydraulic/ Pneumatic surface safety valve, Control, Gate Valves, etc.

Applications: Production and distribution of crude oil, natural gas & other hydrocarbons.

Company Name: Western Valve

Type of Business: Manufacturer

Company’s Address: 201 Industrial Street Bakersfield, CA 93307

Contact Information: Phone: (661) 327-7660

Other Products: Double Isolation & Bleed Expanding Plug valve, etc.

Applications: Multi-product pipelines, metering skids, tank storage, equipment isolation, distribution terminals, commercial aviation, and USA Military fuelling facilities.

Company Name: Volvo Spain

Type of Business: Manufacturer

Company’s Address: Pol. Ind. Kalzadako — Saratxo, E-01468 Amurrio, Alava, Spain

Contact Information: Phone: +34 (945) 891-291

Other Products: Gate, Globe, Plug, Check, Pressure Seal, etc.

Applications: Oil & Gas, Natural Gas, Power generation, etc.

Company Name: Franklin Valves

Type of Business: Manufacturer

Company’s Address: 500 Northpark Central Dr., Suite 100, Houston, TX 77073

Contact Information: Phone: 713.812.7100

Other Products: Plugs, Gate valves, Diverter valves, etc.

Applications: Biofuels, Product Manifolds, Prover Loops, Tanker Terminals, Aviation fuelling, offshore platforms, Blending Units, etc.

Summary

This article provided a brief introduction about a Lubricated Plug Valve, for detailed information about the valve or any other product, you can contact us, and our experts will guide you to select a proper valve according to your requirements.

Thanks for reading this informative article, you can write to us or leave feedback for us in the comment box provided below.