Non Slam Check Valve

Non Slam Check Valve

※ Resilient or Metal Seat

※ Size Range: NPS 2 to NPS 36

※ Pressure Range: 150LB to 2500LB

※ Design STD.: ASME B16.34

※ Non Slam Check Valve Manufacturer

Introduction

In every pressurised pipeline application, a well-designed Check Valve is required to safeguard pumps against reverse flow and pipes from water hammer. Furthermore, the Check Valve should be cost-effective for the operation and have a low head loss feature to decrease power usage.

To close properly, a conventional check valve like a swing check valve relies on gravity or flow reversal. Swing check valves have a tendency to slam when a pump is turned off. Gravity and reversed flow smash the check valve shut, when a pump fails. Water hammer occurs due to this, and as fluid is non-compressible it causes pressure or a shock wave. The fluid continues to flow back and forth until the wave settles due to friction losses. Slamming check valves generate severe pressure surges in a system, which rattles pipes and destroys equipment.

A slam occurs when the disc or ball of the check valve collides with the seat, causing a loud noise. The sound is made by a sound wave generated by a pressure spike straining the pipe wall, not by the physical shutting. The check valve should close prior to any reverse flow that may occur to entirely avoid slamming. Unfortunately, this is not the case. The valve’s shape determines the amount of reverse flow, therefore the faster the valve shuts, the less slamming.

We briefly reviewed the Check Valve Slam phenomena in this article, as well as why Non-Slam Check Valves are better for water hammer prevention. We have also provided a list of the top five Non-Slam Check Valve Manufacturers at the very end of this article.

What is A Non-Slam Check Valve?

Non-Slam Check Valves have become more popular because of their non-slamming characteristic, which also helps in a pipeline pressure surge and water hammer prevention. Now a question arises here, what changes are made in the design of check valves to give them the feature of non-slamming?

The introduction of spring as the opposing force bringing the valve to the original closed position, rather than relying solely on gravity, substantially enhances the variety of their employment in these linearly stroking systems. As the fluid velocity slows upstream, the compression force of the spring on

the valve begins to shut the disc. The disc is entirely closed by the time the upstream velocity reaches zero. The force required to induce water hammer on either side of the valve is significantly decreased with the reverse flow removed. The presence of this kind of spring allows these check valves to be used in a number of pipe orientations, and it is an important component in the construction of non-slam check valves.

Non-slam check valves, also known as silent check valves, have a short-stroke piston and a spring that opposes the piston’s linear motion in the flow direction. The non-slam check valve’s short stroke and spring action allow it to open and close rapidly, reducing the shockwave impact of the water hammer and getting the name silent check valve.

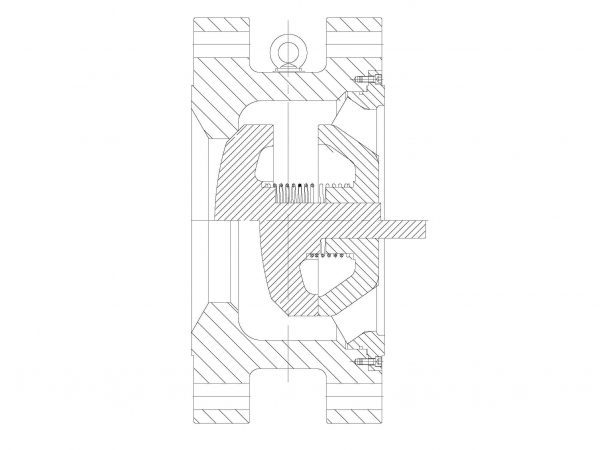

Construction & Working: Non-Slam Check Valve

The Non-slam check valve is designed in a way that it automatically prevents backflow. When the pump is turned on, fluid flows into the valve from the seat end, forcing the disc open and enabling fluid to pass through.

When the pump is turned off, the spring shuts the disc, preventing flow reversal. Due to the kind of closing mechanism, which limits reversal of flow, is the main factor that enables “silent” functioning and eliminates water hammer caused by check valve slam.

The valve body is available with compact wafer ends for assembly between matching flanges or flanged ends.

The disc and the spring are the only moving components of the valve. The disc’s movement is controlled by the body bushing, which ensures that the plug meets the seat uniformly. For drop-tight service, the valve can be equipped with an optional resilient sealing

Application: Non-Slam Check Valve

Non-slam valves are lift-type non-return valves that are used in pipeline systems to prevent fluid backflow while limiting the pressure fluctuations, vibrations, and damages caused by the water hammer effect. Their use is widespread in the chemical and petrochemical industries, steam condensation systems, power generating industry, textile industry, water treatment plants, boilers, and so on. These valves are utilised in a variety of applications, including process lines, hot & cold water systems, heating systems, and oil pipelines.

Features & Benefits: Non- Slam Check Valve

- The full-port enlarged body’s streamlined flow channel eliminates turbulence and reduces erosion and vibration. There is no downtime in the process, and there are no maintenance expenditures.

- The venturi-shaped body’s wide-opened flowing path and high-pressure recovery resulted in very low-pressure drop, lowering pump and compressor running costs.

- A low opening pressure improves the stability of a compressor system at starting. This is accomplished by using a big disc with the same effective pressure regions on both sides (line contact sealing).

- In critical situations such as multi-pump installations or LNG lines, the spring-assisted design enables ultra-fast shutting with almost no reverse flow or pressure spikes.

- The excellent internal design is a possibility due to good mechanical engineering concepts. As a result, axial check valves don’t need to be serviced often.

Top 5 Non-Slam Check Valve Manufacturers

Company Name: ERHARD GmbH & Co. KG

Type of Business: Non Slam Check Valve Manufacturer

Company’s Address: Meeboldstraße 22, 89522 Heidenheim, Germany

Contact Information: Phone: +49 (0)7321 320 0

Other Products: Isolation Valves, Security & Control Valves, Coupling & Fittings, Hydrants.

Applications: Water Treatment/Transmission, Fire Fighting, Irrigation, Gas Distribution, etc.

Company Name: GUSBERTI MARCELLO S.r.l.

Type of Business: Manufacturer

Company’s Address: Via Angelo Mauri 18, Monza (MB) Zip Code 20900, Italy

Contact Information: Phone: +39.039.74.85.51

Other Products: Gate, Globe, Check (Piston, Nozzle, Swing, Tilting, Dual Plate), etc.

Applications: petroleum, water, steam, seawater, chemical, petrochemical, food, power generation, natural gas, etc.

Company Name: SAMSON CONTROLS INC.

Type of Business: Non Slam Check Valve Manufacturer

Company’s Address: 4111 Cedar Boulevard, BAYTOWN, TX 77523-8588

Contact Information: +1 281-383-3677

Other Products: Linear globe, rotary plug, ball, and butterfly control valves.

Applications: Oil & gas, petrochemical, nuclear & traditional power, industrial chemical, household & personal chemical, food & beverage, pharmaceutical, solar thermal, mining & metals, and HVAC industries.

Company Name: Tecofi France

Type of Business: Manufacturer

Company’s Address: 83 Rue Marcel Mérieux, 69960 Corbas, France

Contact Information: Tel: +33 (0)4 72 79 11 75

Other Products: Butterfly, Knife, Regulation, Blow off, Air release, Needle, Pinch, Ball, etc.

Applications: Water, Process Industry, HVAC, Paper & Pulp, Biogas, etc.

Company Name: DFT® Inc

Type of Business: Non Slam Check Valve Manufacturer

Company’s Address: 140 Sheree Blvd. PO Box 566, Exton, PA 19341-0566

Other Products: Check valves, Control Valves, etc.

Applications: Building Maintenance, Chemical Processing, Food & Beverages, Gas, Mining, etc.

Summary

On every pipeline project, a Check Valve is an essential component. Non-Slam check valves are ideal for reducing water hammers since they have the quickest reaction times of any check valve type under pump trip conditions. These valves also close silently, thus they are named silent check valves.

We are one of the leading non-slam check valve manufacturers, we also manufacture a wide range of industrial valves. So, if you are looking for an industrial valve our experts will guide you to find the best product suited for your application according to your need.

Thanks for reading this article, you can write to us or leave feedback in the comment box provided below.