Plug Valve

Plug Valve

The industrial plug valve demand is primarily dominated by waste water and water treatment operations. Waste water treatment is becoming more critical in recent years as a result of significant water crisis in many parts of the world. Furthermore, strict government restrictions and different measures to address the problem of water scarcity have aided the growth of the worldwide plug valve market. Furthermore, the growing demand for plug valves in the oil and natural gas sector, the power generation industry, and the necessity for worker safety all contribute significantly to the market’s growth. Furthermore, the safe functioning, lower energy utilisation of the plug valve, high-performance mechanism, affordability in the production line, decrease in friction, and ease of maintenance boost the overall plug valve market demand.

In this article, we will learn more about plug valves, their operation and construction, types, applications, features and benefits. We are professional plug valve manufacturer. So, keep reading this informative article.

REQUEST A QUOTE FOR MORE DETAILS

What is a Plug Valve?

A plug valve is either a cylindrical or cone-shaped device that regulates fluid flow by rotating inside the valve body. One or more hollow channels are commonly positioned horizontally in plug valves to facilitate easy flow through the valve while it is open. The two-port design with an open and closed setting is the most commonly used type of plug valve. The valve’s two ports are normally on opposing sides, with one passageway connected upstream from one end to downstream at the other and the stem and lever on top. Plug valves provide a direct path through the ports, allowing fluid to flow through the plug valve opening, with very little turbulence. A quarter-turn plug valve is beneficial when rapid and frequent action is required. Valve ends could be flanged, hub-style, or butt welded.

Working: Plug Valve

A plug valve is made up of a plug, in the valve body with a hollow tube. The quarter-turn action aligns the pipe with the hole, resulting in an open condition. The valve sits across the pipe when rotated to a 90-degree angle from the open position, resulting in a closed condition.

Plug valves come in a number of types with differing port openings via the plug.

- Two-Way Plug Valves: The design incorporates a closure element (a plug and a sleeve) in the centre, as well as a straight-through, two-way service for the open and close duties.

Three-Way Plug Valves: These valves have a third port that is usually angled away from the inlet. These plug valves can serve as flow diverting (entry from inlet distributed between one or both outlets) or flow combining (input from inlet directed between one or both outputs).

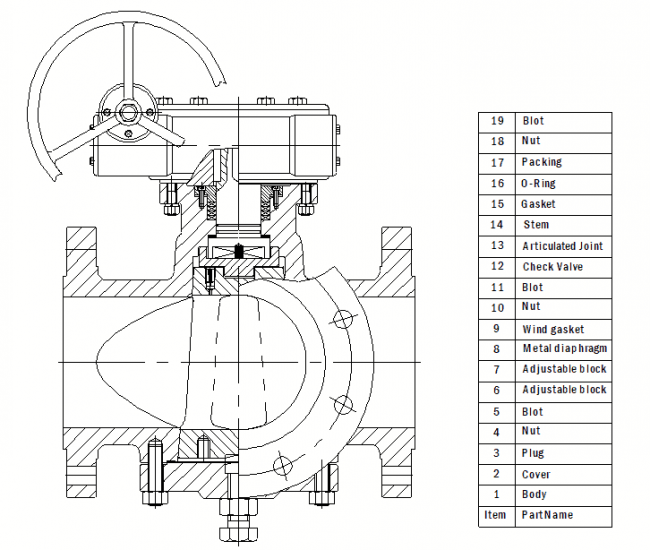

Construction: Plug Valve

Plug valve construction is mostly common and similar to that of other types of industrial valves. Most of the components are similar to other valves, some of those are:

- Valve Body: The valve body, also known as the housing, houses the valve’s intake and outlet ports as well as the rest of the plug valve’s components in a single unit. Valve bodies are made of steel, brass, bronze, carbon steel, stainless steel, aluminium, PVC, or PVDF, among other materials. The material used is determined by the operational circumstances to which the valve will be subjected.

- Valve Plug: The valve plug is the element that acts as the plug valve’s flow control mechanism; it functions similarly to the ball in a ball valve, blocking or allowing fluid flow based on how the valve ports in the plug are connected with the channel in the valve body. Some plug valves feature tapered plugs, while others have cylindrically formed plugs.

- Valve Stem: The valve stem connects the valve plug to the valve (or actuator) handle and allows the plug to revolve when the handle is rotated, causing the valve stem to rotate as well. The stem connects to the exterior of the valve body through the bonnet or cover, which incorporates seals and packing to prevent fluid leakage.

- Valve Port: The valve port is the hole in the valve plug that is carved out. The opening is most commonly rectangular in shape, but it can also be diamond-shaped or round.

Types: Plug Valve

Plug valves are manufactured in various types based on their properties and applications that suits them the best. The main types of plug valve available in the market are:

- Lubricated Plug Valves:

A lubricated valve, as the name implies, employs a lubricant composed of base oil and a viscosity additive that is supplied with pressure between the plug surface and the body seating to minimise friction and seal ports.

Plug valve manufacturers often suggest using a lubricant that is compatible with the process fluid, and valves must frequently be resealed after just a few cycles, if not every cycle. They are commonly employed in applications with infrequent operating since they are considered as high maintenance plug valves.

Lubricated plug valves work effectively in operations that use fluids containing slightly abrasive particles, such as dirty upstream uses, gas distribution systems that require bypass valves, and blow-down valves on valve terminals and kicker valves.

- Non-Lubricated Plug Valves:

A non-metallic flexible sleeve or liner is used in the non-lubricated plug valve. This sleeve is inserted into the valve’s body cavity. The sleeve is pushed against the body by the polished and narrower plug, which acts as a wedge.

The friction present between the plug and the valve body is reduced by using this non-metallic sleeve. Non-lubricating plug valves are advantageous since they require less maintenance. Because of the non-metallic seat, these valves are not commonly used in high-temperature applications. Both lubricating and non-lubricating valves are capable of creating a bubble-tight seal. These valves have the additional benefit of being compact & small in size.

- Eccentric Plug Valve:

A half plug is used in the construction of this plug valve. This half plug is ideal for applications that demand a high seating force and low friction transition from open to the closed condition. Torque-seated valves also provide better shut-off capabilities. Eccentric plug valves are often employed for flow control and isolation in a variety of applications, such as clean and contaminated water, wastewater, sediment and slurries, air, and other services.

- Expanding Plug Valve:

This plug valve is very complex in design and is made up of numerous components that enable it to mechanically expand and serve as a real double block and bleed valve in a single valve. The plug valve has a rotating mechanism that covers both seals from the flow channel by rotating between open and closed conditions.

The body and seals do not come into contact when the valve is in rotation, and as the valve is closed, the slips spread onto the body seat to protect the seals from wear and erosion. They’re frequently utilised to avoid product contamination in instances where double isolation isn’t required.

Advantages: Plug Valve

- As a quarter-turn valve, these valves are able to open and close quickly.

- There is very little resistance to fluid flowing through the valve.

- These valves are compact, have a small size and volume, are lightweight and easy to maintain.

- The plug valve shows a very good sealing performance.

- These valves can be installed horizontally as well as vertically without any limitations.

Application: Plug Valve

As previously stated, plug valves may and have been utilised in a variety of fluid services. In slurry applications, they work well. They’re mostly employed as on-off stop valves in bubble-tight systems. A plug’s wiping action prevents suspended particles from accumulating and forming sludge.

Plug valves are large-capacity valves that may be utilised for directional flow control even in low-vacuum environments. Plug valves are also capable of handling both gas and liquid fuels and can be used in high-temperature applications such as boiler feed, condenser, and other similar components.

Top 5 Plug Valve Manufacturers

Company Name: Flowserve

Type of Business: Plug ValveManufacturer

Company’s Address: Flowserve World Headquarters, 5215 N. O’Connor Blvd., Ste 700 Irving, TX 75039 USA

Contact Information: 972-443-6500

Other Products: Ball, Butterfly, Rotary & Linear Control, Gate, Globe, Plug Valve, etc.

Applications: Oil & Gas, Chemical, Power, Water, General Industries.

Company Name: L & T Valves Limited

Type of Business: Manufacturer

Company’s Address: L&T Campus, TC-1, 2nd Floor, Mount – Poonamallee Road, Manapakkam, Chennai – 600089

Contact Information: +91 98415 67771,

Other Products: Gate, Globe, Ball, Butterfly, Piston, etc.

Applications: Oil & gas, power, petrochemicals, chemicals, water, defence and aerospace.

Company Name: AZ-ARMATUREN GMBH

Type of Business: Plug Valve Manufacturer

Company’s Address: Waldstrasse 7, D-78087 Mönchweiler

Phone: + 49 (0) 7721 7504-0

Other Products: Lined Ball, Control, Actuation/Automation, Special Valve, Sampling Valve.

Applications: Oil & gas, power, petrochemicals, chemicals, water, defence and aerospace.

Company Name: Control Seal B.V.

Type of Business: Manufacturer

Company’s Address: Farmsumerweg 43, 9902 BL, Appingedam, P.O. box 330, 9900AH, Appingedam, The Netherlands

Phone: +31 596 652 222/+31 596 629 405.

Other Products: Axial Flow, Double Block & Bleed Valve, Check Valve, Globe Valve, etc.

Applications: Oil & gas, EPCS, power, petrochemicals, chemicals.

Company Name: Cameron: A Schlumberger Company

Type of Business: Plug Valve Manufacturer

Company’s Address: 5599 San Felipe St, Houston, TX 77056, United States

Contact Information: +971 4 274 2200

Other Products: Low Emission valve, Butterfly, Ball, Gate, Check, Plug / Diverter valves, etc.

Applications: Subsea, Drilling, Production, Gas transmission, etc.

Summary

A well-built and planned plug valve is critical for the high-stress working environments of the many industries that rely on valves for control and other functions. We are a leading plug valve manufacturer with a diverse product line that includes a variety of different valve types. Our team of professionals ensures that the critical systems are of the highest possible quality in order to function under the harshest situations.

Thanks for reading this article, you can write to us or leave feedback in the comment box provided below.