Side Entry Ball Valve

Side Entry Ball Valve

※ Size Range: 2″-42″

※ Class Range: 150LB-2500LB

※ Fire Safe Design

※ Anti Static

※ Anti blow-out

※ Side Entry Ball Valve Manufacturer

What is a side entry ball valve?

Side entry ball valves are types of ball valves that are assembled from the sides. A side entry ball valve consists of three or two-piece of the valve body. The two or three pieces of the side entry ball valve are connected using bolts and nuts. Each piece of a side entry ball valve is made using forging method. After production of the body pieces, they are assembled and connected using bolts. A side entry ball valve made through forging method ensure the valve does not have defects where fluid can leak through. Assembling side entry ball valves is easy and the internal components can be aligned easily. Side entry ball valves use spring-loaded floating seats which remain in contact with the valve ball making it suitable for different applications such as cryogenic applications, high temperature, and high-pressure applications. Side entry ball valves are designed to have high structural integrity to ensure zero thermal deformation due to temperature changes. This ensures high performance in tight shut-off in critical applications such as liquefied natural gas.

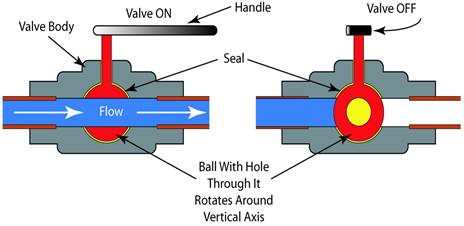

How does a side entry ball valve work?

A side entry ball valve works by using a component known as the ball. The ball is made with a hole at its center. The purpose of the ball is to open and close fluid flow. The ball is connected to the actuator or hand lever through another component known as a stem. The side entry ball valve works by rotating the hand lever or using an actuator. To open a side entry ball valve, the valve operator rotates the hand lever for manual valves at an angle of 90o. The torque applied by the side entry ball valve operator is transmitted to the ball via the stem. This makes the ball make a quarter-turn (90o) similar to the hand lever. In this case, the ball hole in a side entry ball valve becomes collinear with the pipeline allowing fluid to flow through the valve. To close the side entry ball valve, the hand lever or actuator rotates again for 90o in the opposite direction to when it was being opened. This makes the ball hole perpendicular to the pipeline. In this case, the fluid from the pipeline cannot flow since the valve ball is blocking its path.

Types of side entry ball valves

Manual side entry ball valve

A manual side entry ball valve is a valve that is operated by a valve operator. In other words, a manual side entry ball valve depends on human power to open and close. A manual side entry ball valve is designed with a hand lever or handwheel where the valve operator applies torque to open or close the valve. Manual side entry ball valves are simple in design and versatile. The versatility of a manual side entry ball valve is because it can be automated later if the user finds it necessary. Also, manual side entry ball valves are cheaper relative to their actuated counterparts. However, large manual side entry ball valves need a lot of torque from the valve operator to open or close.

Actuated side entry ball valve

An actuated side entry ball valve is a valve that is operated by using an actuator. Actuated side entry ball valves are designed and manufactured without a manual handwheel or hand lever which allows for actuator installation. Actuated side entry ball valves are used together with the actuator to automate the operation of the valve and thus control flow rates. With automation in side entry ball valves there is no need for a valve operator. The actuators for side entry ball valves are electric, pneumatic, and hydraulic actuators. The user or owner of a side entry ball valve is at liberty to decide which actuator he/she can use. Actuated side entry ball valves are very reliable as they can work on their own without a valve operator. Actuated side entry ball valves work well despite high fluid pressure that need a lot of torque to open or close. However, comparing manual and actuated side entry ball valves, the actuated valves are more expensive.

Trunnion side entry ball valve

A trunnion side entry ball valve is a valve with the ball rotating in a fixed position. The design of this side entry ball valve is such that it cannot move in a lateral direction since it is held in position by a shaft known as trunnion. The trunnion holds the ball at the top and bottom sides of the ball. A trunnion side entry ball valve forces a floating seat against the ball using fluid pressure or by pro-stressing the ball and seats. The trunnion side entry ball valve absorbs fluid pressure in the flow. As such, the contact between the seat and the ball is not stressed excessively and the closing/opening torque remains low. This makes a trunnion side entry ball valve easier to operate relative to other valves. Trunnion side entry ball valves are capable of working in crude oil and gas pipelines due to their integrity in high strength and being leakage proof. Trunnion side entry ball valves with three pieces are used for larger-sized valves that allow more fluid flow for a given time. Trunnion side entry ball valves with the standard body have the pieces connected using bolts and nuts while those meant for special applications have the body pieces joined together using the welding method.

What do you consider when selecting/purchasing a side entry ball valve?

Type of media

Properties of the gas or liquid being controlled through the side entry ball valve will determine the material used to make the ball valve. For instance, when a side entry ball valve is to be used to control flow of corrosive or harsh fluids, perfluoroalkoxy alkanes (PFA) and Polytetrafluoroethylene (PTFE) valve seats will be good as they are resistant to corrosion. When the side entry ball valve is to be used to control the flow of gaseous products, it is important to use strong metallic material to make the valve strength integrity.

Application condition

In this case, the question to ask yourself is can this type of side entry ball valve withstand the temperature (give the temperature value), flow rate, and pressure (give the pressure value)? If the side entry ball valve is not selected properly, it will cause performance problems within the valve or somewhere else within the piping system. If there is high temperatures than what the side entry ball valve can withstand then thermal distortion will occur to internal parts of the valve such as seats and rings. This will render the valve nonfunctional and then the need for a new valve or repair. Metallic seats and rings will always have higher thermal resistance compared to plastic seats and rings. Also, metallic components will have higher strength relative to plastic ones for high-pressure applications.

The function of the valve

In this case, know the specific task you need to perform with this side entry ball valve. A side entry ball valve is best for on and off control of the fluid flow. It is not the best valve for throttling applications. However, an aside entry ball valve with a V notch hole at the ball center can be used as a throttling valve. If a side entry ball valve meant for on/off use is used for regulating fluid flow it wears out within a short period.

Actuation method

This refers to the tool used to provide torque to open or close the side entry ball valve. The tool can be a hand lever for a manual side entry ball valve or it can be an actuator for actuated side entry ball valve. For actuated side entry ball valve, it is important to determine the type of actuator to use to get the best service out of that valve.

Maintenance requirements

Some side entry ball valves are designed for standard applications or for special applications. For example, a side entry ball valve with the body fully welded is good for certain applications like crude oil and gas but it cannot be repaired or cleaned while in the field. Unlike the side entry ball valve with an all-welded body, others can be inspected, cleaned, and repaired while in the field.

Applications of side entry ball valves

- Side entry ball valves are used in crude oil and gas transfer.

- Side entry ball valves in pharmaceutical industries since they can be cleaned to enhance high levels of sanitation.

- They are used in water supply applications.

- Side entry ball valves are used in chemical admixtures and treatment.

- These valves are used in food and beverages processing where the valve can be cleaned to enhance hygiene.

- Side entry ball valves are used in feed water and cooling water systems.

- They are used in steam power generation plants.

Advantages of side entry ball valves

- Side entry ball valves are easy to open and close.

- Side entry ball valves are versatile as they can be used in different applications.

- Side entry ball valves are durable because they can be repaired to extend their service.

- These valves have high strength for high temperature and high-pressure applications.

- They are free from fluid leakage.

- These valves can be cleaned easily which makes them suitable for applications that demand high levels of hygiene like food industries.

- Side entry ball valves are easy to install, assemble and repair.

Disadvantages of side entry ball valves

- Side entry ball valves must always be installed vertically.

- These valves close quickly which can cause hammering problems.

- Side entry ball valves have cavities around the seat and the ball which is not suitable for slurries as they can cause valve blockage.

Troubleshooting side entry ball valves

Side entry ball valve has an unsmooth operation

- Slurry or solids in the fluid. Clean interior of the side entry ball valve.

- The ball is corroded by the fluid. Replace the ball with another one that is resistant to corrosion.

- Fluid sticks to the ball and the seats. Clean the interior of the side entry ball valve. Replace the ball and or seats.

External leakage

- Gasket and gland packing seals are damaged. Replace them.

- Bolts and nuts are loose. Tighten the bolts and nuts.

Leakage through the seat

- Damaged seats and ball due to solids and fluid slurry. Clean the slurry and solids. Replace the ball and seats.

- Fluid sticking to the seats and ball. Clean the interior of the side entry ball valve. Replace the ball and seats if necessary.

Summary

A side entry ball valve is a type of ball valve which is assembled from the sides. A side entry ball valve consists of three or two pieces. The assembly of a side entry ball valve is done by connecting the two or three pieces using bolts and nuts. Side entry ball valves are made through forging method. Each piece of side entry ball valve is made and then assembled to form the final product.

There are various types of side entry ball valves which include manual side entry ball valve, actuated side entry ball valve, and trunnion side entry ball valve. Each type of side entry ball valve has its unique characteristics and advantages. Side entry ball valves are used in different applications such as in crude oil and gas, pharmaceutical industries, water supply, food and beverages processing, steam power plants, chemical admixtures and treatment among others.

Advantages of side entry ball valves include quick to open/close, durable, versatile, high strength, suitable for inspection, cleaning, and repair, and easy to install and repair. Factors to consider when purchasing or selecting a side entry ball valve are the type of media, application condition, actuation method, maintenance requirements, and function of the valve.