Sleeved Plug Valve

Sleeved Plug Valve

※ Resilient Seat Sleeved

※ Size Range: NPS 2 to NPS 10

※ Pressure Range: 150LB to 600LB

※ Design STD.: API599/ API6D

※ Sleeve Plug Valve Manufacturer

Introduction

Sleeved Plug Valves are built to last longer and are simple to repair in-line. These are classified among the non-lubricated and belong to the family of quarter-turn valves having a compressible liner or sleeve as the sealing material. In many applications, they can go for decades without being serviced. Sleeved plug valves can be utilised for on/off and regulating service in challenging process applications and a broad range of media working temperatures. These valves are utilised in a variety of industrial applications, including oil & gas, petrochemical, pharmaceutical, chemical fertiliser, and electric power.

In this informative article, our experts will explain more about the sleeve plug valve, construction, features & benefits, specifications, etc. We will professional sleeve plug valve manufacturers.

What is Sleeve Plug Valve?

Sleeved plug valves depend on a tapered or conical elastomeric sleeve rather than an injected lubricant for sealing. This elastomer sleeve rests at the bottom of the plug and is forced against the bodily cavities between the plug and the valve body. This sleeve (or liner) reduces the friction between the plug and the valve body while also ensuring that the valve is bubble-tight.

Owing to their low maintenance requirements non-lubricated sleeved plug valves can also be utilised in situations where it is difficult to carry out maintenance, such as systems with reactive fluids or toxic compounds such as sulphur and hydrogen fluoride. But sleeved plug valves, on the other hand, are restricted by the temperature and chemical tolerance of the non-metallic materials used in their construction. The compact size of these valves gives an extra advantage.

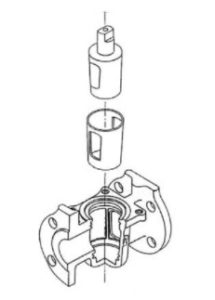

Construction: Sleeve Plug Valve

In a sleeve plug valve, each component has its specific purpose for creating this robust valve design. The main components of a sleeve plug valve are the body, sleeve, cover, top seal, and cover are considered as main valve components.

- Body: The body of a sleeved plug valve is cast as a one-piece that provides high integrity. This casting has integral design features that are important for creating key benefits of the product being cavity-free and maintenance-free.

The body casting has 360-degree lips around the ports which keep the sleeve in place preventing sleeve rotation while the valve is being operated. The sleeve relief area present in the body allows the PTFE sleeve to expand and contract during the temperature changes, this relief area also assists in controlling the valve torque.

The body of the sleeve plug valve also consists of horizontal and vertical ribs which enables strong sealing capabilities between the sleeve and the plug by creating compression that is needed to maintain the sleeve in its place along with 360-degree lips.

- Sleeve: A fluorocarbon sleeve that keeps the tapered plug in place and maintains a continuous seal. The sleeve provides the lubricity required to turn the valve, allowing it to open and close quickly, function without maintenance, be non-sticky, and last longer.

- Top Seal: In sleeve plug valve design, the top seal ensures that fugitive emissions are kept to a minimum. It complies with or surpasses the most strict regulatory criteria currently in effect. The integrated, flexible graphite stem seal and the graphite cover seal ring ensure sealing where the stem and at the body/cover connects.

- Cavity-free design: The cavity-free design is a significant feature of the product and is crucial in applications where solids are present in the media. The key valve components the body the sleeve and the plug are in close contact with each other creating the cavity-free design. This means that there are no spaces between the plug and the body that can trap media when the valve is being operated.

Features & Benefits: Sleeve Plug Valve

- These sleeved valves have an economical and compact design, bi-directional in nature, actuation is very simple, lightweight, and the fluid handling system is flexible and compact.

- The plug is entirely enveloped in an inert PTFE sleeve. From port to port, the sleeve offers a broad circumferential sealing surface. The sealing is guaranteed whether the valve is open, closed, or turning. This sealing capability cannot be matched by any ball or gate valve.

- The sleeve is firmly inserted into the body of the valve. Sleeve confinement is ensured by high-pressure ribs, top and bottom retention, and 360° port lips present in this design.

- The 360° port lips enable a self-cleaning action as the plug rotates, removing scaling and sticking material due to which there is no seizure and sticking of the plug.

- The friction coefficient of the PTFE sleeve is very low. It has lubricating properties. Even if the valve is kept unoperated in any condition for long periods of time, ease of operation is ensured.

- Standard pricing and a significantly prolonged service life ensure extremely lower long-term costs of ownership.

- The stem sealing on the sleeve plug valve is made up of cup springs that guarantee consistent forces acting on the sealing element and the plug. This results in zero emissions and a longer life cycle.

- There are no cavities in the body where flow material can collect and contaminate subsequent processing. This cavity-free construction also keeps things from sticking together.

Technical Specification: Sleeve Plug Valve.

- Size Range : NPS ½ to NPS 24

- Class Range : ANSI Class 150 – Class 600

- Design Standard : ASME B16.34

- End Connection : Flanged ASME B16.10

- Valve Body Material : Carbon Steel / Stainless Steel

- Temperature Range : -30°C to 260°C

- Sleeve : PTFE / CFT / GFT

- Operation : Manual Lever / Pneumatic / Electrical

Top 5 Sleeve Plug Valve Manufacturers

Company Name: Flowserve

Type of Business: Plug Valve Manufacturer

Company’s Address: Flowserve World Headquarters, 5215 N. O’Connor Blvd., Ste 700 Irving, TX 75039 USA

Contact Information: 972-443-6500

Other Products: Ball, Butterfly, Rotary & Linear Control, Gate, Globe, Plug Valve, etc.

Applications: Oil & Gas, Chemical, Power, Water, General Industries.

Company Name: AZ-ARMATUREN GMBH

Type of Business: Manufacturer

Company’s Address: Waldstrasse 7, D-78087 Mönchweiler

Contact Information: Phone: + 49 (0) 7721 7504-0

Other Products: Lined Ball, Control, Actuation/Automation, Special Valve, Sampling Valve.

Applications: Oil & gas, power, petrochemicals, chemicals, water, defense, and aerospace.

Company Name: Crane ChemPharma & Energy

Type of Business: Plug Valve Manufacturer

Company’s Address: 4526 Research Forest Drive, Suite 400, The Woodlands, TX 77381 USA

Phone: +1-936-271-6500

Other Products: Butterfly, Ball, Diaphragm, Globe, Check Valves, etc.

Applications: Oil & gas, power, petrochemicals, chemicals, water, mining, Pharma, etc.

Company Name: G M ENGINEERING PRIVATE LIMITED

Type of Business: Manufacturer

Company’s Address: Survey no 168, Village Dhokaliya, Via Metoda 360021, Rajkot 360 101, Gujarat

Contact Information: Phone: +91 92280 05558,

Other Products: Butterfly, Ball, Diaphragm, Globe, Check Valves, etc.

Applications: Refineries, Petrochemical Plants, Chemical Industries, Nuclear Plants, Oil industries, Pharmaceutical Plants, Fertilizers, Mining industries, Sewage Plants, Water Treatment, Water Supply Plants, Thermal Plants, etc.

Company Name: FluoroSeal

Type of Business: Plug Valve Manufacturer

Company’s Address: 1875 46th Avenue, Lachine, QC H8T 2N8, Canada

Contact Information: +1 514 739 0220

Other Products: Butterfly, Ball, Lined, Globe, Check Valves, etc.

Applications: Oil & Gas, Chemical, Petrochemical, Power, Pharmaceutical, and Mining.

Summary

Thanks for reading this article, for more information on our wide range of products you can contact us. You can also write to us or leave your comment and feedback about the article in the box provided below.