Top Entry Ball Valve

Top Entry Ball Valve

※ Fire Safe Design

※ Anti Blow Out Stem

※ Size Range: NPS 2 to NPS 28

※ Class Range: 150LB to 2500LB

※ Design STD.: API6D/ API608/ ISO17292

※ Top Entry Ball Valve Manufacturer

Introduction

The global industrial valve market covers a wide range of applications of various valve designs depending on the end-user requirements. However, when it comes to reliable and repeatable shut-off performance along with the highest levels of safety and quick in-situ maintenance, Top entry ball valve is the most preferred design.

Carrying out in time and regular maintenance of any valve is crucial for its optimal performance and longer service life which requires the system to be completely isolated. This maintenance downtime has been reduced by the top entry ball valve manufacturers as the valve is designed so that the inspection and maintenance activities can be carried out in place.

So, in this article, we will understand the basics of top entry ball valves, from construction and working to their types and applications.

What Is A Top Entry Ball Valve?

A top entry ball valve is a part of the “quarter-turn” type valve family. This design of the ball valve allows access to the internal parts of the valve by simply removing the bonnet on top of the valve.

Usually, these valves are made from single metal casting, making them more suitable for high-pressure applications. In addition, the valve construction has minimal thread connections, which minimize any possible leak path.

Over the years, top entry ball valve manufactures have designed these valves with technically advanced features to operate in severe service conditions. As a result, these valves provide excellent corrosion resistance and superior sealing performance at both high and low pressures.

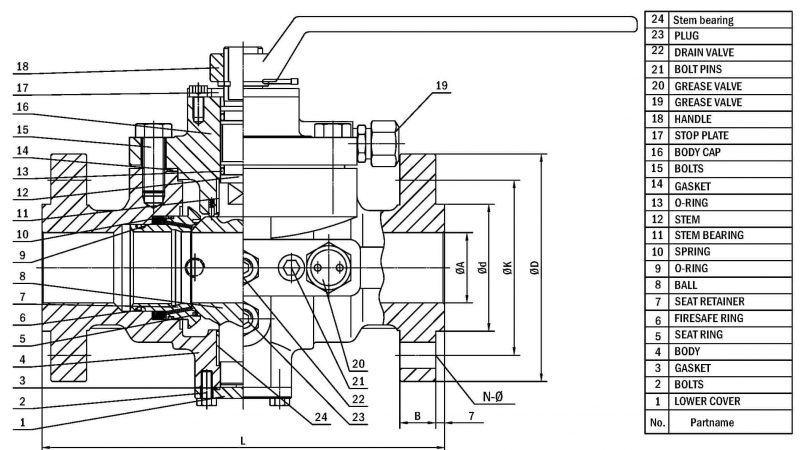

Construction Of Top Entry Ball Valve

The constituents of the top entry ball valve are pretty similar to any other ball valve design. It contains a valve body, hollow ball, stem, and an operating handle (manual or automatic).

As the name suggests, the difference in the construction of this valve is that top entry ball valves can be assembled and disassembled from the top. In general, the top entry configuration of the valve changes the location of the valve seat.

The top entry for these valves is designed in such a way that the valve seat consists of a V-shaped outer circle. It is angled to the contact portion of the control rod, reducing the stress on the control rod and the contact surface of the valve seat, thereby improving the service life.

The V-shaped outer circle allows the valve seat to be detached from the valve body, making room for top entry. In addition, several other design changes may be adopted by top entry ball valve manufacturers to stand out in the market.

Top Entry Ball Valve: Working

A shaft, or stem, turns the top entry ball valve by an angle of 90 degrees (a quarter turn) to operate it. The driving modes include manual operation, worm and worm gear transmission, pneumatic operation, and electric operation.

The port is covered or uncovered as the ball rotates, permitting or preventing the passage of fluid media. The valve is open when the bore is facing in the direction of the conduit, allowing fluid to flow in.

Due to the design of the valve seat, when the stem drives the ball to the bottom of the seat, there is no pressure on the stem during the entire period of operation. Regardless of pipeline forces imposed against the rigid single-piece body, the double sealing action of the main O-ring and completely enclosed graphite seal assures zero leakage and maximum safety assurance.

Classification Of Top Entry Ball Valve

Top entry ball valves can be classified as per ball support and bore profile.

Classification as per ball support

- Top entry floating ball valve

- Top entry trunnion mounted ball valve

Classification as per bore profile

- Top entry reduced bore ball valve

- Top entry full bore ball valve

Top Entry Ball Valve: Technical Specifications

- Size Range : NPS 2 to NPS 28

- Class Range : 150LB to 2500LB

- Design Standard : API6D / API608 / ISO17292

- Fire Standard : API 607 or API 6FA

- End Connection : RF / RTJ / BW

- Operation : Manual Lever / Pneumatic / Electrical

- Pressure Rating : ANSI Class 150 to Class 2500

- Body Materials : Carbon steel, ITCS, Stainless steel, Duplex, Super Duplex, Inconel 625 and other special alloys

- Top Mounting : ISO 5211 / EN15081

- Temperature Range : -196°C to +200°C (-320°F to +392°F)

- Pressure Testing : API 598 / API 6D / EN 12266-1/ISO 5208

Top Entry Ball Valve: Special Features

Let us now understand some special features incorporated by top entry ball valve manufacturers in the design of these valves.

- Valve has a top entry body design with bolted cover for full in-line and field maintenance/reparability.

- A one-piece body design is used to ensure adequate strength and rigidity at the maximum-rated operating pressure for the body.

- The stem is not loaded by the ball side thrust, ensuring low operating torque and high durability.

- Sufficient margin wall thickness is provided, exceeding the minimum requirements of ASME B16.34, along with high-strength connective bolts.

- It has an anti-blow-out bottom entry stem that is shouldered to the body. Also, the retention of the stem is not dependent on any intermediary bolted component.

- Vent valve for block & bleed function and seat integrity verification.

- Firesafe cover gasket protected by O-ring as a primary seal.

- Double O-ring as primary sealing for valve stem. All seals can be field replaced without the need to remove the cover or stem from the valve with the vent valve open.

- Single piston effect pressure & spring-assisted seat design for bi-directional positive sealing at high and low pressures with positive cavity relief.

- Provisions made for emergency sealant injection for seat and stem seal.

Advantages of Top Entry Ball Valve

While different top entry ball valve manufacturers incorporate different elements in their designs, the fundamentals remain the same. It is the design of the valve which provides the additional benefits such as

- In-situ maintenance

- Less fluid resistance

- Simple structure, adequate strength, and rigidity

- Reliable sealing

- Rapid on-off operation

- Less operating torque

- Minimum deformation of the valve seat

- Longer service life

Disadvantages of Top Entry Ball Valve

There are certain limitations to the use of top entry ball valve, which includes

- The valve is the heaviest among the quarter-turn ball valve family.

- Slightly expensive than other valve designs.

- Throttling action is not recommended.

How Is Top Entry Ball Valve Different From Side Entry Ball Valve?

The term top and side entry refer to the way by which the ball of the valve and its internal parts can be accessed, i.e., from the side (side entry) or the top (top entry). Usually, the top entry design is used where frequent in-line maintenance of the valve is expected.

Here is a list of major differences in the design of the top and side entry ball valve.

- Generally, the top entry ball valves are cast steel bodies, while the side entry valve design is manufactured with (robust) forged steel bodies.

- Top entry ball valves have a monolithic structure (i.e., made in a single piece), while the side entry valve design has a two- or three-piece assembly.

- Because of their cast bodies, top entry ball valves require more non-destructive testing than side entry valves.

- Side entrance ball valves are simpler to manufacture and install than top entry ball valves, which need a significant amount of skill and expertise to make them perfectly operational.

- Due to the casting procedures needed to create the body, top entry ball valves are often more costly and have longer lead times than side entry valves.

Summary

To summarize, we can say that the design features of the top entry ball valve contribute towards the valve’s capability to provide the highest levels of performance and reliability. This valve design ensures a high degree of safety for both plant and personnel with positive sealing of all external leak paths despite repeatable shut-off operation.

If you’re reading this post, we’d like to thank you for your time and hope you find the content informative.

For further information about top entry ball valves or other product inquiries, please feel free to contact us. You can also comment and share your opinion about our products with us.