Triple Offset Butterfly Valve

Triple Offset Butterfly Valve

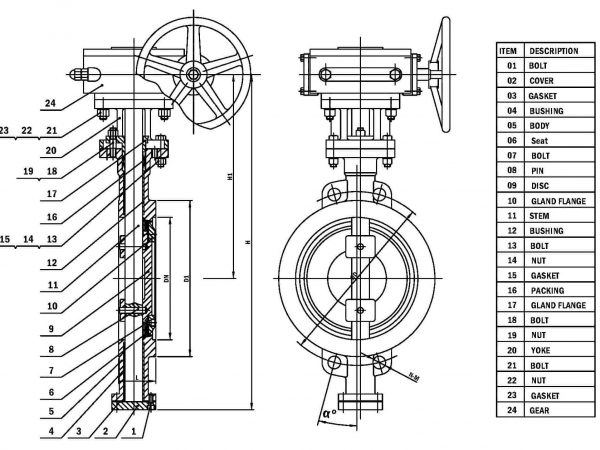

※ Triple Offset Disc

※ Size Range: NPS 2 to NPS 48

※ Class Range: PN16/25/40/150LB/300LB

※ Design STD.: API609/ MSS SP-68

※ Triple Offset Butterfly Valve Manufacturer

Introduction

In recent years, the market for triple offset butterfly valves has grown significantly. Due to the increased demand in substitution of zero offset and double offset butterfly valves throughout finished goods industries, this rise is expected to continue in the future years. These valves are used in a variety of sectors, such as oil and gas, water and wastewater treatment, and others. As a result of increased discoveries of new oil and gas resources, as well as the requirement of water and wastewater management projects owing to water shortage, will provide opportunities for their implementation and boost their market share in the future years.

Triple offset butterfly valves are often used in the oil and gas sector for high-temperature liquids and gases, as well as applications where pressure exceeds 150 pounds per square inch (PSI). With greater longevity, efficiency, and lower operational cost, these valves outperform other traditional valves. The triple offset butterfly valve seat is engineered to reduce wear, cut maintenance costs, and increase the valve’s service life. In addition, triple offset butterfly valves’ zero leakage sealing qualities allow operations to run safely and efficiently even in harsh situations.

What is Triple Offset Butterfly Valve?

In the entire range of the valve family, a triple-offset butterfly valve is the most unique and advanced valve. This valve is capable of working efficiently in high-pressure and temperature environments with a leak-proof performance. This type of butterfly valve features a metal-to-metal sealing configuration, making it effective even in critical situations.

A Triple-Offset Butterfly Valve (TOV) is the most advanced type of butterfly valve that is almost similar to a double-offset butterfly valve but has an additional offset. It is commonly used in critical applications. The additional third offset belongs to the axis where the disc & seat touch each other. The seat surface has a conical design, which, when combined with a similar shape at the disc’s rim, results in very less contact before the valve fully closes, which allows the disc to make a seal with the seat without friction. A butterfly valve with three offsets is more effective and wear-resistant. Metal seats are commonly used in triple offset butterfly valves to generate a bubble-tight shut-off. As the metal seats are employed in triple-offset butterfly valves, they can be used for applications with higher temperatures.

Features & Benefits: Triple Offset Butterfly Valve

- Triple offset Geometry: The stem shaft of a Triple-offset Butterfly Valve is displaced from the sealing surface plane and the body centreline. A third offset is created by rotating the sealing imaginary cone away from the bore centreline. The triple-offset design guarantees that only the last shut-off position brings the body and disc into contact. Due to which interference wear is eliminated, driving torque is reduced, and the product’s service life is extended.

- Controlled Operating Torque: Unlike the position-seated ball, butterfly, and plug valves, the sealing force of triple-offset butterfly valves is generated by externally transmitted torque instead of mechanical interference. This ensures that the cone-to-cone sealing is created by contact pressure rather than friction caused by the seat’s elastic deformation. This characteristic enables these valves to manage high-pressure ratings while maintaining a consistent and precise working torque.

- Leak-Proof Performance: These advanced valves are designed as per the fugitive emission standards of ISO 15848 which makes them leak-proof and preferred valve design for applications where the system is handling hazardous medium.

- Metal Seats: Metal-to-metal sealing guarantees that the valve can withstand a wide range of temperatures, pressures, and fluid varieties. The distinctive shaped metal seal ring used in triple offset valves has elastic qualities that allow radial compression to be evenly distributed over the sitting surface. These are the important factors in the valve’s zero leakage ability.

No Rubbing Actuation: By removing friction between the disk and the seat during opening and shutting, the sealing parts and the valve as a whole will last longer. When this feature combines with the fundamental feature of quarter-turn rotation, allows faster and easier valve actuation over time and modulation even at extremely low angles.

Technical Specification: Triple Offset Butterfly Valves

- Size Range : NPS DN 80 to DN 2500

- Class Range : ANSI Class 150 – Class 1500

- Design Standard : API 609 Cat B

- End Connection : ASME B16.5 / ASME B16.47 Series A/B

- Valve Body Material : Carbon Steel / Stainless Steel / Low Temp Steel / Low Alloy CS

- Temperature Range : -195°C to 550°C

- Operation : Manual Lever / Pneumatic / Electrical

Application: Triple Offset Butterfly Valve

Triple offset butterfly valves feature fire-safe technology and heat resistance, as well as they, are sufficiently strong to sustain high pressures without any leakage. As a result, they are an ideal choice for power generation industries such as thermal power plants. They are also a better choice to be used in oil refineries and petrochemical industries that deal with hazardous & reactive substances. These valves are free of elastomers and other corrosive components, allowing them to withstand all the substances they come into contact with.

Triple offset butterfly valves can effectively work in high water pressures, thus they’re a good choice for water treatment facilities. Valves with either one or two offsets risk succumbing to pressure, but the triple offset valve’s three offsets offer greater safety. Instead of depending on one seat to take all the load, the linked offsets and their geometric design work in harmony to open and close the valve disc.

Top 4 Triple Offset Butterfly Valve Manufacturers

Company Name: Bray International

Type of Business: Triple Offset Butterfly Valve Manufacturer

Company’s Address: 13333 Westland E Blvd # 203, Houston, TX 77041, United States

Contact Information: +1 281 894 5454

Other Products: Butterfly, Knife Gate, Control, Ball Valve, etc.

Applications: Chemical, Food Beverages, HVAC, Marine & Shipbuilding, Mining, etc.

Company Name: Adams Armaturen GmbH

Type of Business: Manufacturer

Company’s Address: Baukauer Str. 55, D-44653 Herne, Germany

Contact Information: Phone: +49 (2323) 209-0

Other Products: Butterfly Valve, High-Performance Valves, Check Valves, etc.

Applications: Power generation, petrochemical processes, district heating processes, the sugar and paper industry, metallurgy as well as oil, gas, water, and wastewater applications.

Company Name: Cameron: A Schlumberger Company

Type of Business: Triple Offset Butterfly Valve Manufacturer

Company’s Address: 5599 San Felipe St, Houston, TX 77056, United States

Contact Information: +971 4 274 2200.

Other Products: Low Emission valve, Butterfly, Ball, Gate, Check, Plug / Diverter valves, etc.

Applications: Subsea, Drilling, Production, Gas & Liquid transmission, etc.

Company Name: Emerson

Type of Business: Manufacturer

Company’s Address: 8000 West Florissant Avenue, St. Louis, MO 63136, United States

Contact Information: +1 314 553 2000

Other Products: Control, Isolation, Solenoid, Relief Valves, etc.

Applications: Nuclear Plants, Subsea, Petroleum Industry, etc.

Summary

With several excellent sealing properties, Triple Offset Butterfly Valves are substantially more efficient and durable under high pressure and temperature conditions. Its offset construction and technology ensure that it is long-lasting and requires little maintenance.

Call us for more details on this valve or any other type of industrial valve, and our specialists will assist you in selecting the ideal product for your requirement.