V-Port Ball Valve

V Port Ball Valve

※ Size Range: 2″-16″

※ Class Range: 150LB-2500LB

※ Fire Safe Design

※ Anti Static

※ Anti blow-out

※ V Port Ball Valve Manufacturer

Introduction

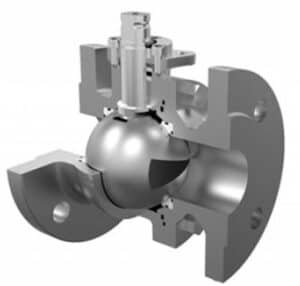

Ball valves, which are quarter-turn valve family members, provide dependable sealing and are the best choice for gas operations needing a tight shutdown. The seating is less suitable for throttling situations due to the possibility of continuous wear on the seats. Although they are normally made of steel, more robust nickel-plated versions are also available.

Ball valves feature a spherical closing element that controls the flow by turning it on and off. A port (or bore) runs through the centre of the ball, and when that port is oriented parallel to the pipeline, it is in the open state and will permit fluids to pass through. When the bore is turned 90 degrees, it becomes perpendicular to the flow channel, shutting the valve and obstructing fluid flow.

Two-way ball valves are among the most commonly used type because they provide linear fluid motion from the intake to the exhaust. Flow can go in a variety of directions, even at 90-degree angles, using three-way and four-way ball valves. The four primary body types are top-entry, split-body, three-piece body (side or end-entry), and totally welded. The valve action is roughly the same in all the types of ball valves. Ball valves come with one of three primary types of bores: full port, reduced port (also recognized as standard port), or v-port.

Various control operations, like services involving minor pressure fluctuations, have utilized and continue to use standard round port ball valves. Today, a wide spectrum of control applications are accessible with greater flow control thanks to the invention of V port ball Valves. Due to the requirement that the flow velocity is regulated in accordance with the application, this kind of ball valve is sometimes referred to as a control valve. As a leading producer of V Port ball valves, we offer reasonably priced, high-quality goods like V notch control ball valves.

What is a V-Port Ball Valve?

Specialized ball valves called V-Port ball valves are excellent for precise controlling applications. Additionally, they can offer dependable cut off at the same time. With the exception of having a “characterised” rather than “circular bore” through the ball, these valves are built similarly to full or standard port ball valves. It either features a “V-shaped bore of the ball” or a “v”-shaped seating, as the name implies. The flow curve is evened out by this characterisation, making them appropriate and occasionally preferable for control purposes.

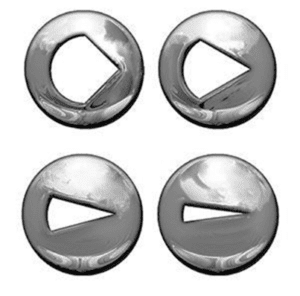

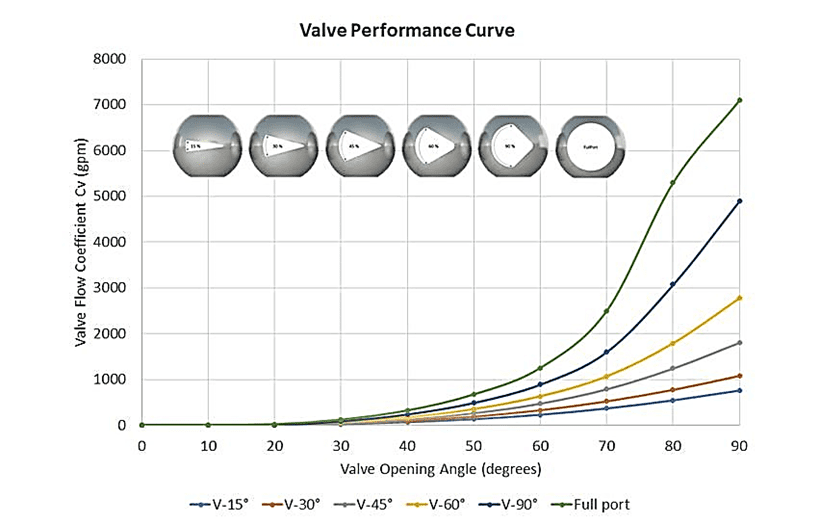

To accommodate various flow levels with the same valve body, several alternative V-Port balls are available. The most popular are 60, 30 and 15 degrees. Due to its ability to provide linear flow characteristics, V-port ball control valves are typically chosen for fluid control. The flow characteristics of a v-port ball valve are distinct from those of normal port ball valves. A v-port ball valve’s flow pattern increases linearly when the shaft rotation advances. The exceptional robustness of V-ball control valves allows them to resist the high velocity of fluids passing through them.

Working: V-Port Ball Valve.

As V-port ball valves open from their closed state, the little end of the “v” lifts first. This enables reliable flow control at this point. The increased fluid velocities may harm normal valves, hence the design often demands a more durable structure. The accuracy of a globe valve, pressure regulating valve, balancing valve, or needle valve is said to be superior to that of a v-port valve, despite it being a control valve.

Construction Features: V-Port Ball Valve.

In V-port ball valves, the ball’s typical bore has a cross-section in the shape of a “V,” instead of the conventional round cross-section. These designs come in a range of internal angles, from 15 degrees to 90 degrees, and some allow for the retrofitting of ball valves from round bore to V-port configurations. When a small pressure drop or tight shutdown is desired in high-flow rate operations, the V-port ball is employed in place of a circular bore ball. In contrast to circular bore designs, which are extremely non-linear, a V-port ball valve can give a better quality of flow control or rangeability and can reach a linear flow pattern as a function of the actuator position. A few construction features are listed below.

- Ball valves with v ports have self-lubricating bearings on both the upper and lower surfaces. They are mounted within the valve body. The valve stem and the bearing have a sizable contact area. Consequently, it has a low friction coefficient and a large load capacity. Additionally, it aids in lowering the valve’s torque.

- The sphere is coated with long-lasting chromium, and the sealing valve seat is welded with a tough alloy after it has through a hardening process like ion nitriding.

- PTFE valve seats exhibit excellent sealing ability and resistance to corrosion.

Technical Specification: V-Port Ball Valve.

- Size Range : NPS ¼ to 12 (DN 6 – DN 300)

- Temperature Range : -50° F to 650° F (-45°C – 345°C)

- Design Standards : ASME B16.34, ASME B16.10(Face to Face)

- Pressure Range : ASME Class 150, 300, 600

- Body Material : Carbon Steel (WCB), and Stainless Steel (CF8M)

- Seat Material : Metal, PEEK, RPTFE, and TFM

- Ball Material : Stainless Steel (CF8M)

- Certification : ATEX, NACE MR0175, PED, PE(S)R, SIL, TR CU, API 607, PE(S)R

- End Connections : Socket welding, butt welding, threading, and flanged end

Features & Benefits: V-Port Ball Valve.

This quarter-turn control v-port ball valve is more compact, lightweight, and far less costly than similar sized globe valves and segmented control valves provided by other V-port ball valve manufacturers. Because of the advantages of ball valves and modern digital actuation control, our control valves respond quickly to control inputs. These valves fulfil Class VI standards and provide a bubble-tight shutdown with no leaks. Superior rangeability and consistency, high flow capacity, the ability to operate with fluids that contain particles and fibres, a simple maintenance process and an excellent connectivity with PLCs and computerized communications are further benefits. High-quality pneumatic and electric controller devices are extremely reliable and effective.

- Precision Flow Control: V-port control ball valve apertures come at a variety of angles and give equal proportion flow patterns. To attain the required flow rate, rotate the ball between 0 and 90 degrees. A notched ball and a ball with a small angle aperture, like a 15° ball, provide an inherited linear flow characteristic, whereas a ball with a medium angle opening, like a 30-degree V port, provides an optimised equal percentage flow characteristic. To satisfy specific control requirements, custom ports are also designed by V-port ball valve manufacturers. Fluid flow in pipe systems could be more accurately controlled with precise flow control. The Cv and control characteristics are readily modified by only switching out the ball since they were developed with adaptability in process settings in mind.

- Linear Flow: Stream fluid flows linearly through the pipe system as a result of the in-line architecture featured by v-port ball valves. Increased media control and quick responses to controller signals are provided by the straight pattern.

- Low Pressure Drop: Fluids typically flow in a straight line through V-port ball valves. Pressure drop through the valve is reduced by the straight flow. The flow coefficient (Cv) of v-port ball valves is unusually high in comparison to other control valves. Smaller V-ball control valves can be used to obtain the same flow rate as other bigger control valves thanks to the high Cv value.

- Reliable Shut-off: The floating ball mechanism utilised in V-ball valves improves flow management and helps to provide a bubble-tight shut-off. When it shuts, the upstream pressure pushes the ball on the seat. This creates a seal that is airtight. V-port ball valves are suited for gas applications due to the bubble-tight seal.

Differences: V-Port Ball Valve & Globe Valve.

There are various things to take into account when choosing a control valve for any application, including:

- Globe valves come in two-way flow control, three-way mixing, and three-way diverting configurations. V-Port Ball Valves are made available only in two flow control configurations.

- Globe valves are not frequently employed in situations requiring a bubble-tight shutdown. The “floating ball concept,” which is used by V-Port Ball Valves, ensures a bubble-tight closure. The seal is strengthened when the valve is closed because the upstream pressure forces the ball against the downstream seat.

- In comparison to V-Port Ball Valves, Globe Valves give a higher degree of control capabilities.

- For high-cycle applications where the valve must be regularly changed to maintain stringent specifications, globe valves are significantly better suited. Due to the v-port ball’s consistent interaction with the seats, repeated rotation of these seals will cause the seals to wear out more quickly.

Application: V-Port Ball Valve.

Ball valves featuring V ports have several uses and industries where they can be employed. These industries, for instance, cover the manufacturing sector, gas production, and transmission & storage. The water treatment system, industrial food processing, transporting acid in industries, agribusiness, wastewater handling, and pharmaceutical industries are further applications for V port ball valves. Such a wide range of applications for these ball valves is made possible by the reliable flow control of V port ball valves.

V port ball valve is also appropriate for the regulation of systems comprising fibres and suspended solids as well as liquid media including acid, water, and others.

Summary: V-Port Ball Valve.

When compared to control valves of the same size, V-port ball valves have optimum flow characteristics that are significantly higher. They are also compact, lightweight, and less expensive. The most precise flow control is provided by the Stainless Steel V-Ball Valve and Flanged Stainless Steel V-Port Ball Valve in a small ball valve box.

I hope you now have a basic understanding of v-port ball valves. Please let us know what you need in the comments area. We will help you select the ideal valve based on your needs. Please feel free to post any feedback or recommendations in the box below.