Wedge Gate Valve

Wedge Gate Valve

※ OS&Y Gate Valve

※ Size Range: NPS 2 to NPS 48

※ Class Range: 150LB to 2500LB

※ Design STD.: API600/ API603/ ASME B16.34

※ Wedge Gate Valve Manufacturer & Supplier

What is a wedge gate valve?

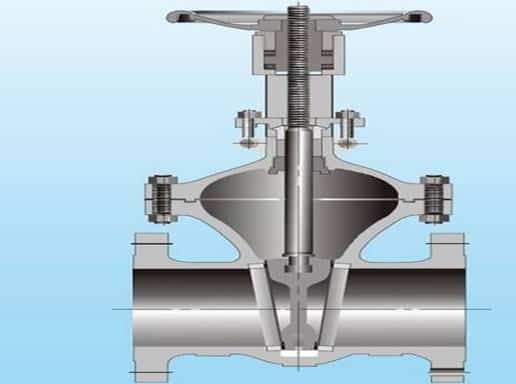

A wedge gate valve is a type of gate valve that employs a wedge gate perpendicular to the fluid flow to either open or close that flow. As the name suggests, a wedge gate valve consists of a tapered gate/disc. Wedge gate valve manufacturers design the valve to have an empty bottom when it opens. The importance of wedge design in this gate valve is to increase the auxiliary sealing load. This design helps to have a metal-sealed wedge valve that can stop fluid flow both at high pressure and at low pressure. There are various types of wedge gate valves. These valves are based on design and size. Such varieties help customers/end-users to select a valve that best fits the application they need to work on. In addition, wedge gate valves are used in various applications ranging from residential to industrial applications.

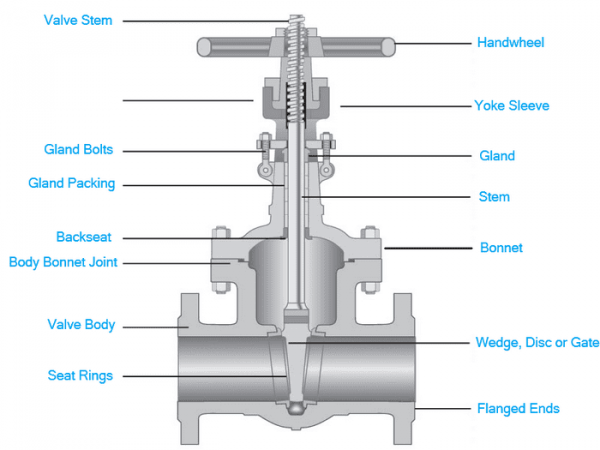

Components of wedge gate valve

Handwheel/actuator

In wedge gate valves, a handwheel is used when the valve is manual. When the valve is not operated by hand, it has to get its torque (power) to open/close from an actuator. The handwheel and actuator do the same function: to turn the stem to open/close the valve.

Valve body

The valve body in a wedge gate valve is the main component that houses almost all internal parts of the valve. The valve body must be made of strong material to help it withstand high pressure and high temperatures associated with the media flowing. Depending on the expected use of a particular wedge valve, the valve can be made of either metallic or plastic material. However, most wedge gate valves are metallic and are used mostly in high pressure and high-temperature application. The plastic wedge gate valves are used in applications that have low pressure and low temperatures. The metallic materials used to make wedge gate valves for high pressure and temperature applications are preferred because of their good mechanical properties such as high strength, high hardness, high thermal resistance, and some degree of ductility.

Stem

The stem is the component of wedge gate valves used to transfer the torque applied on the handwheel to the gate to open/close the valve. The stem is also made of strong material like the valve body to help it withstand high internal pressure and temperature. The size/thickness of the stem depends on the torque required to open the wedge gate valve. Wedge gate valve manufacturers design the stem depending on the size of the valve: smaller valves have smaller stems while larger valves have large stems. The stem is connected to the gate/disc that raises or lowers to open/close the valve.

Bonnet

Bonnet is the component of a wedge gate placed on top of the valve body to cover internal components. The bonnet is either screwed or bolted to form a tight seal of zero leakage. There are four types of bonnet connection methods which are screw-in, bolted, pressure seal, or union. The type of bonnet used by the wedge gate valve manufacturer depends on the indented use of that particular valve.

Gate

The gate/disc is the part of a wedge gate valve used to block fluid flow. The gate moves linearly upwards or downwards to block fluid flow. For wedge gate valves, the disc/gate used is of wedge shape. The design strength of the gate used depends on certain factors among them pressure and temperature levels to ensure it cannot be distorted by high pressure or high temperature.

Seat

Seat refers to an interior component of a wedge gate valve that contacts the gate to form a tight-seal free from leakage. Wedge gate valve manufacturers design these valves such that when the stem moves linearly upwards/downwards, the gate contacts with the seat when the valve is closed. The seats used in wedge gate valves are either in terms of seat rings or integrated into the body. The seats integrated into the body are made of the same material as the body whereas the seats threaded or pressed into the body enhance more variation.

Gaskets

Gaskets are mechanical packings or seals used in wedge gate valves to prevent fluid leakage from the valve.

Trim

Trim refers to the internal components of a wedge gate valve. These components include stem, gate, bushing, seating surface, and stem hole guide.

How does a wedge gate valve work?

A wedge gate valve works by raising and lowering its gate. This helps to open and close the gate thus allowing fluid flow or stopping fluid flow. The power to raise or lower the gate in a wedge gate valve comes from the handwheel or the actuator. The handwheel or lever is used for manual wedge gate valve while actuated valves used actuator. The handwheel/actuator is used to rotate the stem. The stem is connected to the gate. So, when the stem is rotated several times it provides torque to raise or lower the gate thus opening or closing the valve. The stem has threads that enhance the upwards or downwards movement of the gate. In wedge gate valves, stem vertical movement and fluid flow rate are non-linear. This means that the most notable changes occur near valve shutoff. When the wedge gate valve is partially opened at high velocity it aids in seat and gate wear. As such, this reduces the service life of the wedge gate valve.

Types of wedge gate valve

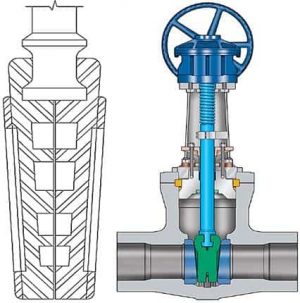

Rising stem wedge gate valve

The rising stem wedge gate valve is designed with threads external to the body of the valve. The stem moves upwards when the valve opens. Rising stems are mostly made of forged or cast steel. Rising stem wedge gate valves have high strength to work at high pressure. For the rising stem wedge gate valve, it is visually possible for the valve operator to check how far the valve has opened. As such, the operator can easily tell when he/she has closed/opened the valve by looking at the stem exposed.

Non-rising stem wedge gate valve

These are wedge gate valves where the stem does not protrude the handwheel. These are wedge gate valves designed so that when the handwheel is turned far-right the valve is closed whereas when it is turned far to the left the valve is open. These valves take less space relative to the rising stem counterparts. As such they are suitable for limited space applications. In some non-rising stem wedge gate valves, the manufacturer installs an indicator for closed/open position that indicates the level of opened-closed valve.

Flexible wedge gate valve

This is a wedge gate valve with the gate having a cut around its perimeter. The cut varies in depth, size, and shape. A gate with a wider and deeper cut enhances flexibility although it compromises valve strength. When the cut is narrow and shallow, it gives less flexibility but high strength. Flexible wedge gate valve design enhances seat alignment as well as tight seal free from leakage. Valves of flexible wedge gate design improve valve performance where there is thermal binding as these valves are used in steam systems. Sometimes the steam lines expand due to thermal heat distorting the valve body which may cause thermal expansion. With a flexible gate, the gate flexes when the seat compresses due to thermal expansion emanating from the steam pipeline and helps to prevent thermal blinding. However, flexible wedge gate valves make the fluid collect in the gate which may cause corrosion weakening the gate.

Screwed-bonnet wedge gate valves

This is a wedge gate valve in which the bonnet and the valve body are connected using screws. These valves are ideal for high-pressure applications as they can provide a tight seal free from leakage.

Bolted-bonnet wedge gate valve

This is a wedge gate valve that uses bolts and nuts to connect both the bonnet and valve body. These valves are the most popular wedge gate valves. These valves use a gasket to seal the joint created between the bonnet and the body. Bolted-bonnet wedge gate valves are used in high-pressure applications as they can provide a tight-seal free from leakage.

Welded-bonnet wedge gate valve

This is a wedge gate valve in which the valve body and the bonnet are welded together. This type of valve is used where leak-proof is paramount and in applications of high pressure and high temperatures. Welded-bonnet wedge gate valves are lighter in weight relative to bolted-bonnet wedge gate valves.

Pressure-seal bonnet wedge gate valves

This is a wedge gate valve that is designed to use system pressure to enhance forces against the body’s internal diameter and the surface of the bonnet. When the system pressure is increased, the force on the gasket increases enhancing a tight seal free from leakage. This type of wedge gate valve is used for high-pressure and high-temperature applications.

Applications of wedge gate valve

- Wedge gate valves are used in petroleum industries.

- These valves are used to work on air, liquids, and vapor.

- Wedge gate valves are used to work on high-pressure and high-temperature applications.

- They are used in powder and slurry applications.

- These valves are used in steam power plants.

- They are used in water pipelines and fire protection systems at low pressure and temperatures.

- Wedge gate valves are used in the food processing industries.

- These valves are used in mining industries.

- Wedge gate valves are used in irrigation systems for shut-off and opening water flow even at high water pressure.

Advantages of wedge gate valve

- Wedge gate valves have low fluid resistance. These valves have minimal fluid flow resistance because of a straight flow channel allowing the fluid to flow without changing direction.

- Energy-efficient. Wedge gate valves are among energy-efficient valves because the fluid flow direction is perpendicular to the gate. As such, wedge gate valves consume less power when closing or opening the gate relative to other valves like the globe valve. The factor of energy efficiency helps to reduce the cost of energy for valves operated using actuators.

- Wedge gate valves employ a simple body design. The valve body is mostly connected to the bonnet using a simple method like screws and bolts and nuts making it easier to open them in times of repair and maintenance.

- Wedge gate valves have bi-directional flow. These valves can be used in any direction as the operators may need.

- Wedge gate valves have minimal erosion. Relative to other valves, these valves experience low levels of erosion on the sealing surface when fully open. The minimal erosion is due to the tight seal used in wedge gate valves.

- Wedge gate valves have small pressure drops. These valves are designed to enhance laminar fluid flow which then results in low-pressure drop.

Disadvantages of wedge gate valves

- Wedge gate valves close and open slowly.

- Wedge gate valves need a large area for installation, operation, and maintenance.

- Wedge gate valves need high torque, especially when used in high-pressure applications.

- Wedge gate valves cannot be used for throttling applications.

Wedge gate valves produce high levels of noise and vibrations when opened partially.

What should you consider when selecting wedge gate valves?

Type of media

The properties of the media being controlled through the valve will determine the wedge gate valve material. When the valve is indented for use in corrosive fluids PTFE and PFA materials would do best as they can withstand corrosion. When the wedge gate valve is meant for use in high pressure and high-temperature applications, metallic valves would be better as they can withstand high pressure and avoid thermal distortion.

Conditions of the application

Selecting the right valve size is the most important consideration when selecting a wedge gate valve for a particular application. When the valve is not properly selected it can cause valve or system failure. The valve size will depend on the flow rate expected as well as maximum temperature and maximum pressure. Metallic wedge gate valves will withstand high pressure and high temperature relative to plastic valves.

The function of the wedge gate valve

Know the specific task you would like to do with the valve. Wedge gate valves are specifically used for shut-off and opening fluid flow. This valve should not be used for throttling applications as it will get damaged very soon.

Maintenance requirements

In this case, consider wedge gate valves that are easy to disassemble for repair and maintenance. Such valves include screw and bolted wedge gate valves which are easier to repair relative to welded-bonnet wedge gate valves. Bolted and screw wedge gate valves are easy to open the top cover for cleaning and removing clogged debris.

Actuation method

Before purchasing a wedge gate valve first find out how you would like to operate the valve. Will it be manual, pneumatic, electric, or hydraulically actuated? Some actuators can help in making the valve automated or semi-automated which reduces the labor required during operation. The manual valve will need an operator who has to turn the handwheel to open/close the valve.

Troubleshooting wedge gate valves

Leakage in wedge gate valve

- Seat leakage. This could be due to foreign material logged under the wedge. Open the wedge gate valve enough to flush the debris at high velocity. Repeat this process several times until the leakage stops. If the leakage persists, open the valve to check if there is damage to the wedge. If it is damaged replace it.

- Leakage through the stem. Check O-rings for damage. Replace as necessary if damaged. Also, check the packing glands to see if they are properly tightened. If not, tighten them.

- Leakage through the body. Check for damaged, cracked body or bonnet. If damaged replace as necessary.

- Leakage through bolted connections. This could be due to loose bonnet-body bolts, loose stuffing boxes, or end joints. Tighten them as necessary. NB: The tightening of loose components should be done before pressurizing the line. If the system is pressurized, relieve the pressure before tightening the bolts/screws.

Wedge gate valve is not operable or is hard to operate

- This could be due to pipeline testing. Before pipeline pressure is relieved, open the valve to relieve trapped pressure.

- Applying excess torque on a wedge gate valve can make operating parts permanently damaged. An excessive torque is commonly associated with power actuators. Actuator output torque should be adjusted to suit the wedge gate valve. The first or last turns of the valve should be done by hand.

- This could as well result when the wedge gate valve has not been used for a long time causing excess build-up which then affects valve closing/opening operation. Exercise the valve one rotation at a time from open to a closed position to help remove internal buildup.

Summary

A wedge gate valve is a valve that uses a wedge gate to open/close the fluid flow. Wedge gate valve manufacturers design the valve such that the fluid flow is perpendicular to the gate/disc. Such design helps to reduce pressure drop since fluid flow losses pressure when it changes direction. In a wedge gate valve, fluid flows straight without change in direction which in other valves reduces chances of pressure loss.

The wedge gate valve as the name suggests has a tapered gate/disc. The wedge gate valve with a wedge gate helps to increase the sealing load. Wedge gate valves are bi-directional valves. These valves are made of different materials ranging from metallic to plastic. Also, wedge gate valves are of different sizes and designs which helps customers to select the best valve for their applications.

Wedge gate valves are used in various applications such as water supply, mining, pharmaceutical, food processing, chemical industries among others. When selecting a wedge gate valve you need to consider five major factors which are a type of media, the function of the valve, actuation method, maintenance requirements, and condition of the application to get the best valve for that application. Advantages of wedge gate valves include Low fluid resistance, energy-efficient, simple design, bi-directional flow, small pressure drop, minimal erosion among others.