Y Type Strainer

Y Type Strainer

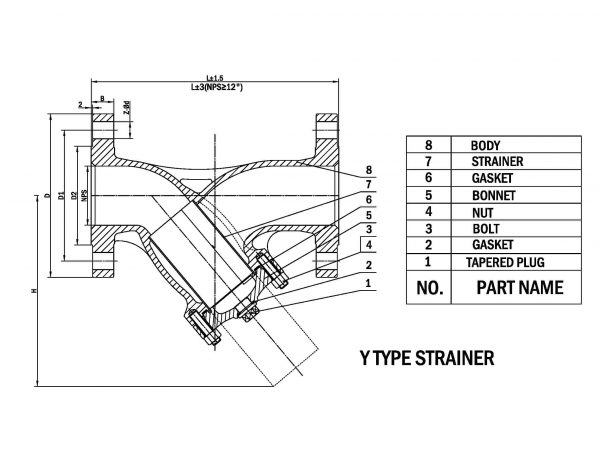

※ Y Pattern/ Bolted Bonnet

※ Size Range: NPS 1/2 to NPS 32

※ Class Range: 150LB-600LB

※ Design STD.: BS3532/ ASME B16.34

※ Y Strainer Manufacturer

Introduction

It’s critical to understand the distinct functions and features that distinguish each strainer before picking which one to utilize. The same is true for Wye strainers as well. While this strainer type is more versatile than basket strainers, the Y-type strainers have a confined installation. The function of a y type strainer is precise, which is exactly what makes them excellent for the situations in which they may be employed. This indicates that understanding the function of the Y-type strainer and the applications that benefit from it, is the best approach to obtain the results you want from it!

What is a Y-type Strainer?

A Y-type strainer is named so because of its design that implicates a Y shape. These types of strainers are generally used for high-pressure operations like steam, but these can also be employed in vacuum or suction conditions. It has a compact cylindrical shape and a very strong body. They are able to handle the pressure as much as 400 bar.

Working: Y-type Strainer.

The filtering leg is joined to the main pipeline at an angle in the Y strainer, which has the shape of a ‘Y’ and is termed as Y Strainer. A Y-type strainer is most commonly employed in high-pressure pipelines, steam, liquid, or gas.

These strainers require a frequent cleaning as Y-type strainers have a less capacity to hold the dirt due to their compact design. Except when significant levels of rust are present, or where substantial amounts of debris may be introduced immediately after commissioning, this is typically not a concern with steam systems.

The blow valve is generally fitted into the strainer cap in situations where substantial amounts of debris are present, allowing the strainer to be cleaned using steam pressure without shutting down the operation.

Construction: Y-type Strainer.

A Y-type strainer got the name from its shape like a “Y” and is used to separate particles from steam, gas, or liquid. A filter element constructed of mesh, perforated metal, or a wedge wire straining element allows for this mechanical straining process. A wire mesh is the most frequent straining element. Some have “blow-off valves” that make cleaning easier in settings where there is a lot of debris blowing around. The strainer is formed like a Y and is compact. Because the fluid travels through the filter with minimal change of direction, the Y shape provides superior flow characteristics than, say, a T-shaped strainer.

Material of Construction: Y-type Strainer.

Y-type strainer manufacturers construct a wide range of strainers using various material and their alloys. Choosing a proper type of Y-type strainer is very crucial when using a specific piping system. When they are fitted in a piping system, they help to remove solids and debris from the system fluid. As a result, they work to protect & increase the life of system equipment such as pumps, steam traps, flow meters, etc. which prevent the system from downtime and breakdown maintenance.

Different types of body materials used by Y-type strainer manufacturers to fabricate these valves are:

- Stainless Steel: It is the most commonly used material type which is used in applications where freedom from contamination and corrosion resistance is a key requirement. These valves are used in food, pharmaceutical, and chemical industries. The initial setup cost of these valves is comparatively higher them strainers made of other materials.

- Cast iron Y strainers are often utilized in pipe systems that do not have high pressures or temperatures, as well as systems that are not subjected to significant thermal or mechanical shock. Cast iron is the most broadly utilized strainer body material. It’s utilized for larger-diameter potable water lines, non-potable water systems, and a range of other products and processes.

- Carbon steel Y strainers are employed at high pressures and temperatures, and they are highly resistant to thermal and mechanical shock due to their strength and durability. They’re also employed in applications where there’s a risk of fire. The oil and petrochemical industries mainly employ carbon steel bodies.

- Bronze: Dirt, rust, and glue may all be removed from pipe systems using bronze Y strainers. Brackish, saline, and marine applications, as well as potable water services, frequently employ bronze body y strainers. Although, they are more expensive than some of the other alternatives.

- Brass Y strainers are a cost-effective alternative for a variety of uses. Upstream installations frequently employ brass to protect regulators, pumps, and control valves from undesirable materials such as corrosion and pipe scale.

- PVC and CPVC: Y-type strainers made of PVC or CPVC (polyvinyl chloride or chlorinated polyvinyl chloride) are a commonly used material for removing dirt, debris, and other solids from the industrial piping system. They can sustain high pressures and are easy to install because they can be placed vertically or horizontally. PVC can only handle temperatures of up to 140° Fahrenheit, but CPVC can endure temperatures of up to 200° Fahrenheit. They are corrosion and chemical resistant to a high degree. Because PVC and CPVC are such flexible materials, these kinds of Y strainers may be used in a variety of applications. They are very affordable when compared to other alternatives.

There are many different types of pipe applications. As a result, it’s critical to select the appropriate pipeline components, constructed of the suitable material, for the job. Y strainers come in a variety of materials, including the ones mentioned above. As you can see, each material is best suited to various applications and pipe systems. When you employ Y strainers made of the appropriate material for your pipeline, you can expect more efficient operation, less downtime, and longer equipment lifespans.

Installation: Y-type Strainer

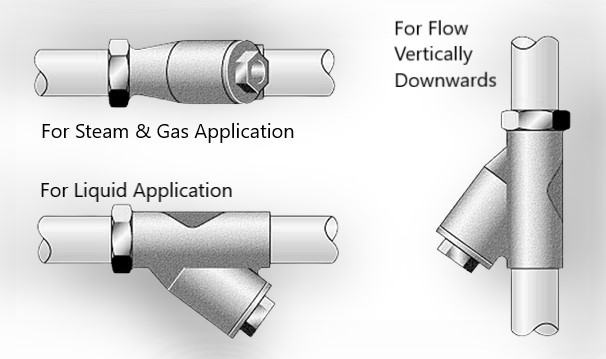

- With the screen element pointed downward, a Y-strainer can be mounted in either a horizontal or vertical position (Downward flow). This enables the strainer screen to gather particles in the strainer at the screen’s lowest position.

- The Y-type strainer should be fitted in horizontal steam or gas pipe with the pocket in the horizontal plane. This prevents water from gathering in the pocket, which can lead to erosion and interfere with heat transfer.

- The pocket in a liquid system should point vertically downwards. During low flow circumstances, this prevents the debris from being pushed back into the upstream pipework.

- Although it is preferable to place strainers in horizontal lines, this is not always practical, and they can also be installed in vertical pipes if the flow is vertically downward, so in that case, the debris will naturally fall into the pocket.

Application: Y-type Strainer.

Y strainers can be used in many types of systems with different system fluids and the different parameters at which they operate. Some of those fluids are:

- Steam: A Y-type strainer’s most prevalent use is in steam applications. Benefitted by its design, a y strainer can withstand the high pressure and temperature which is seen in steam applications.

- Liquids: For these medium, the main solid particles that are to be separated from are send and gravels. When the system is used with water handling applications these strainers help to protect the equipment from getting damaged by separation of debris and undesirable solid particles.

- Air and Gases: As these strainers are suitable for high pressure applications, they can also be used for Natural gas and Air system. These systems also show high operating temperatures which a Y-type strainer can easily handle.

Y-type strainers can be used in various sectors and applications, materials that is to be used is chosen by studying the proper requirement and condition for which it is chosen. When it comes to industrial and commercial applications, keeping in mind the characteristics can help you get the most out of a y strainer.

Summary

When compared to other types of strainers, the possibilities for customizing y strainers appear limitless. However, for this technique to work, the design of a y strainer must be acceptable for the purpose. Always be careful to know the application you’re dealing with before purchasing a y strainer to ensure you obtain the best results.

If you’re reading this, we appreciate your time and hope you find the information useful.

For further information about Y-Type Strainers or other product inquiries, please feel free to contact us. You may also leave a comment and share your thoughts with us about our products.